Bingo TIG mochini tjheseletsa

Re Lebele Ka Liketso!

Mohlala o Tummeng o Latelang

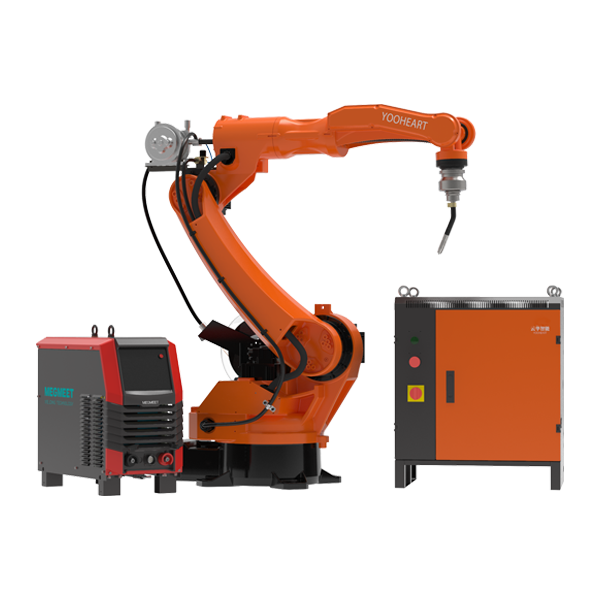

TIG welding Power source, Manual & Robot model, Tšehetsa mekhoa e fapaneng ea puisano

WSME 315/400/500/630

Mochini o kentsoeng oa AC le DC pulse argon arc welding

Mesebetsi:

TIG e sa feleng ea AC, AC pulse TIG, DC TIG kamehla, AC pulse TIG, manual mental-arc welding.

Indasteri ea likopo:

Aerospace, karohano ea sebaka, indasteri ea petrochemical, mochini o futhumatsang mocheso, thepa ea ka tlung ea aluminium le leseli la libaesekele.

Likaroloana:

Phanele ea ts'ebetso e nang le sebopeho se loketseng, mesebetsi e ruileng le ts'ebetso e bonolo;

◆ Paramethara ea welding e ka hlophisoa esale pele;

◆ Maqhubu a maqhubu a AC le bophara ba ho hloekisa bo ka fetoloa ka mokhoa o ikemetseng ho finyella litlhoko tsa ts'ebetso ea welding bakeng sa lihlahisoa tse fapaneng tsa aluminium;

◆ E na le seteraeke se bonolo sa arc, arc e tsitsitseng ea motlakase le letamo la weld le laoloang habonolo;

◆ The argon arc welding e ka sireletsa sethunya sa welding hore se se ke sa fokotseha;

◆Mokhoa oa ho cheseletsa o ka laoloa hole;

◆ Ho kenella ha weld le bophara ba weld bo hlokehang ke motsoako oa weld le palo ea waveform e ka fumanoa ka ho fetola sekhahla sa pulse, frequency frequency, duty ratio, alternating current, AC frequency, clean proportion le AC bias ratio ha AC argon. arc welding e sebelisoa ho lelefatsa bophelo ba ts'ebeletso, e sebetsang ka ho khetheha ho welding ea othomathike le welding ea liroboto.

| Mohlala | WSME- -315R | WSME-400 | WSME-500 | WSME-630 |

| Lebelo la motlakase / maqhubu a lekantsoeng | Mekhahlelo e meraro380V (+/-) 10% 50Hz | |||

| E reitiloe matla a ho kenya (KVA) | 12.1 | 17.1 | 25.7 | 34.7 |

| Lintlha tse kentsoeng hajoale (A) | 18.5 | 26 | 39 | 53 |

| E lekanyelitsoe ho tšoarella ha mojaro (%) | 60 | 60 | 60 | 60 |

| Motlakase o sa keneng motlakase (V) | 63 | 70 | 79 | 79 |

| Sephetho sa hajoale (A) | 5~315 | 5-400 | 20 ~ 500 | 20-630 |

| Arc e qala hajoale (A) | 10~315 | 10-400 | 20 ~ 500 | 20-630 |

| Tlhōrō ea hona joale (A) | 5~315 | 10-400 | 20 ~ 500 | 20-630 |

| Arc e emisang hajoale (A) | 5~315 | 10-400 | 20 ~ 500 | 20-630 |

| Nako ea pele ho nako (S) | 0.1-15 | |||

| Nako ea ho emisa ha khase (S) | 0.1-20 | |||

| Pulse frequency (Hz) | 0.2-20 | |||

| Pulse duty (%) | 1 ~ 100% | |||

| Maqhubu a AC (Hz) | 20 ~ 200 | 20 ~ 200 | 20 ~ 100 | 20 ~ 100 |

| TIG setaele sa arc sa sefofane | HF arc | |||

| Tšusumetso ea hona joale (A) | 30-315 | 50-400 | 50-500 | 50-630 |

| Mokhoa oa ho pholisa | Pholiso ea metsi | |||

| Boemo ba ho itšireletsa | H/B | |||

WSM 315/400/500

Mochini o kentsoeng oa DC pulse argon arc welding

Mesebetsi:

DC kamehla TIG, DC pulse TIG, manual metal-arc welding.

Indasteri ea likopo:

Indasteri ea petrochemical, sekepe sa khatello, kaho ea matla a motlakase, sekepe, baesekele, matla a nyutlelie le ho beha lipeipi.

Likaroloana:

◆ Phanele ea ts'ebetso e nang le moralo o hlakileng, mesebetsi e mengata le ts'ebetso e bonolo;

◆ Parameters tse kang ho phahama butle le ho theoha butle ha motlakase, maqhubu a motlakase, tekanyo ea mosebetsi, nako ea phepelo ea khase e tsoetseng pele le phepelo ea khase e lahliloeng e ka hlophisoa esale pele;

◆ The manual metal-arc welding e ka fetola motlakase oa arc striking and thrust, ka ho otla habonolo ha arc le ho thibela ho khomarela molamu oa welding;

◆ The argon arc welding e ka sireletsa sethunya sa welding hore se se ke sa fokotseha;

◆ E na le mehato e 'meli le mehato e mene ea ho laola welding;

◆E nyane, e bobebe ebile e loketse ho sisinyeha;

◆Mohaho le motlakase li ka bontšoa ka nako e le 'ngoe.Hona joale welding e ka hlophisoa esale pele;

◆TIG e ka khetha mokhoa oa ho phahamisa maqhubu a phahameng a arc striking.

| Mohlala | WSM-315 | WSM-400 | WSM-500 | ||

| E lekanyelitsoe matla a motlakase / maqhubu | Phase e meraro380V(+/-)10% 50Hz | ||||

| E reitiloe matla a ho kenya (KVA) | 11.2 | 17.1 | 23.7 | ||

| Lintlha tse kentsoeng hajoale (A) | 17 | 26 | 36 | ||

| E lekanyelitsoe ho tšoarella ha mojaro (%) | 60 | 60 | 60 | ||

| DC ea hona joale Welding current (A) | 5~315 | 5-400 | 5-500 | ||

| DC pulse | Tlhōrō ea hona joale (A) | 5~315 | 5-400 | 5-500 | |

| Motheo oa hajoale (A) | 5~315 | 5-400 | 5-500 | ||

| Pulse duty (%) | 1-100 | ||||

| Pulse frequency (Hz) | 0.2-20 | ||||

| TIG | Arc e qala hajoale (A) | 10-160 | |||

| Arc e emisang hajoale (A) | 5~315 | 5-400 | 5-500 | ||

| Nako ea pele ho nako (S) | 0.1-15 | ||||

| Nako ea ho emisa ha khase (S) | 0.1-20 | ||||

| TIG setaele sa arc sa sefofane | HF arc | ||||

| Hand arc welding tjheseletsa hona jwale (A) | 30~315 | 40-400 | 50 ~ 500 | ||

| Mokhoa oa ho pholisa | Phodiso ya metsi / Phodiso ya moya | ||||

| Sehlopha sa tšireletso ea likhetla | IP21S | ||||

| Boemo ba ho itšireletsa | H/B | ||||

WSM -S/YS 400

Mochini o kentsoeng oa DC pulse argon arc welding

| Mohlala | WSM-400S/YS | ||

| E lekanyelitsoe matla a motlakase / maqhubu | Phase e meraro380V(+/-)10% 50Hz | ||

| E reitiloe matla a ho kenya (KVA) | 17.1 | ||

| Lintlha tse kentsoeng hajoale (A) | 26 | ||

| E lekanyelitsoe ho tšoarella ha mojaro (%) | 60 | ||

| DC ea hona joale Welding current (A) | 5-400 | ||

| DC pulse | Tlhōrō ea hona joale (A) | 5-400 | |

| Motheo oa hajoale (A) | 5-400 | ||

| Pulse duty (%) | 1-100 | ||

| Pulse frequency (Hz) | 0.2-20 | ||

| Nako ea pele ho nako (S) | 0.1-15 | ||

| Nako ea ho emisa ha khase (S) | 0.1-20 | ||

| Mokhoa oa ho sebetsa oa arc stoping current | Mehato e 'meli, Mehato e mene | ||

| TIG setaele sa arc sa sefofane | HF arc | ||

| Mokhoa oa ho pholisa | Phodiso ya metsi / Phodiso ya moya | ||

| Sehlopha sa tšireletso ea likhetla | IP21S | ||

| Boemo ba ho itšireletsa | H/B | ||

Mesebetsi:

TIG e sa feleng ea DC, DC pulse TIG.

Indasteri ea likopo:

Indasteri ea petrochemical, sekepe sa khatello, kaho ea matla a motlakase, sekepe, baesekele, matla a nyutlelie le ho beha lipeipi.

Likaroloana:

◆ Phanele ea ts'ebetso e nang le moralo o hlakileng, mesebetsi e mengata le ts'ebetso e bonolo;

◆ Parameters tse kang ho phahama butle le ho theoha butle ha motlakase, maqhubu a motlakase, tekanyo ea mosebetsi, nako ea phepelo ea khase e tsoetseng pele le phepelo ea khase e lahliloeng e ka hlophisoa esale pele;

◆ The manual metal-arc welding e ka fetola motlakase oa arc striking and thrust, ka ho otla habonolo ha arc le ho thibela ho khomarela molamu oa welding;

◆ The argon arc welding e ka sireletsa sethunya sa welding hore se se ke sa fokotseha;

◆ E na le mehato e 'meli le mehato e mene ea ho laola welding;E nyane ebile e bobebe ebile e loketse ho sisinyeha;

◆Mohaho le motlakase li ka bontšoa ka nako e le 'ngoe.Hona joale welding e ka hlophisoa esale pele;

◆TIG e ka khetha mokhoa oa ho phahamisa maqhubu a phahameng a arc striking;

◆ Sistimi ea phepelo e matla ea terata e hahelletsoeng ka hare e na le menyetla e mengata ea ho fepa ka terata, e ka fihlelang litlhoko tse fapaneng tsa ts'ebetso;

◆Sekhahla sa phepelo ea terata le lebelo la ho otla ha hona joale ka tsela e iketsang.

Ho nahanela Welder

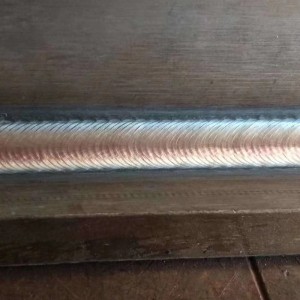

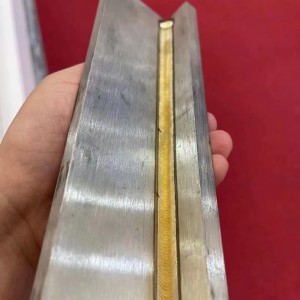

Ha lipoleiti tse peli tsa tšepe tse nang le botenya bo fapaneng li kopantsoe hammoho, e le ho qoba khatello e tebileng ea khatello ea kelello e bakoang ke phetoho e potlakileng ea karolo ea sefapano, bohale ba sejana se teteaneng hangata bo fokotsoa butle-butle ho finyella botenya bo tšoanang metseng e 'meli.Matla a tsitsitseng le a mokhathala a manonyeletso a butt a phahame ho feta a mang.Bakeng sa likhokahano tlas'a ho fapanyetsana, meroalo e tšosang kapa ho sebetsa ka har'a mocheso o tlase le likepe tse nang le khatello e phahameng, hangata ho khethoa ho cheselletsa manonyeletso a butt.Tokisetso ea pele ho tjheseletsa ea motsoako oa lap e bonolo, kopano e loketse, 'me deformation ea welding le khatello e setseng e nyenyane, kahoo e atisa ho sebelisoa ha ho kenngoa manonyeletso le mehaho e sa hlokahaleng setšeng.Ka kakaretso, li-lap ha li loketse ho sebetsa tlas'a maemo a kang ho fapanyetsana meroalo, mecha ea phatlalatso e senyang, mocheso o phahameng kapa o tlaase.Tšebeliso ea li-T-joints le likhutlo tsa sekhutlo hangata li bakoa ke litlhoko tsa sebopeho.Litšobotsi tsa ts'ebetso ea li-welds tse sa phethahalang tsa li-fillet ho manonyeletso a T li tšoana le li-welds tsa fillet holim'a lirope.Ha weld e perpendicular ho tataiso ea matla a ka ntle, e fetoha fillet e ka pele.Ka nako ena, sebopeho sa sebaka sa weld se tla baka likhato tse fapaneng tsa khatello ea maikutlo;khatello ea kelello ea penetration fillet weld e tšoana le ea motsoako oa butt.

Ke Hobane'ng ha U re Khetha

RETS'ELISITSOE

BINGOo tsoela pele ho etsa lipatlisiso le ho ntlafatsatheknoloji ea ho tjheseletsa e bohlalelumella lisebelisoa tse ngata tsa tjheseletsaea lefatše lohle

RETS'ELISITSOE

Joale e se e angoa ebile e ratoake linaha tse ngatanakong e tlang

RE TSOHLE

Re tla tsetela lisebelisoa tse ngata hor e tsoelang pele le d le tlhahisoeya pelele ka mohla u se ke ua emisa