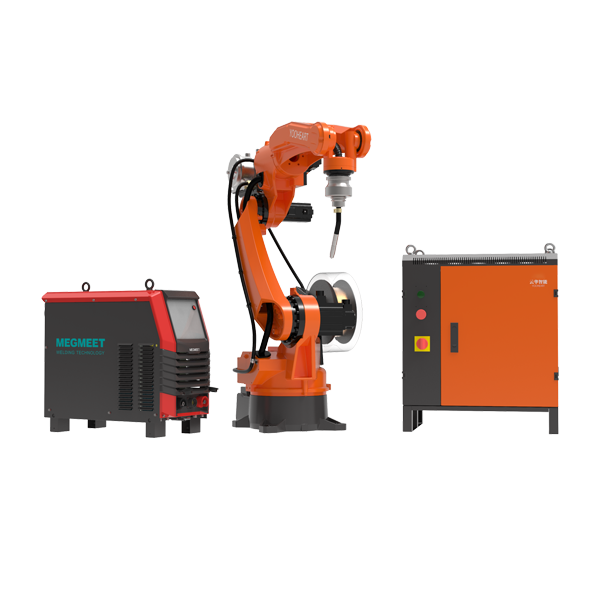

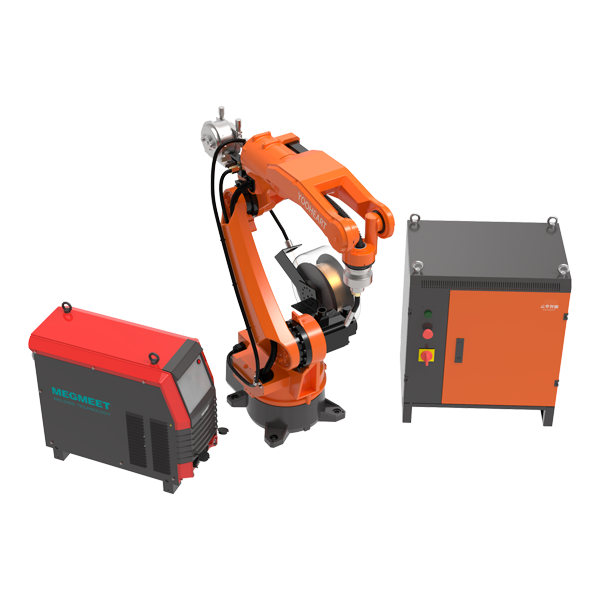

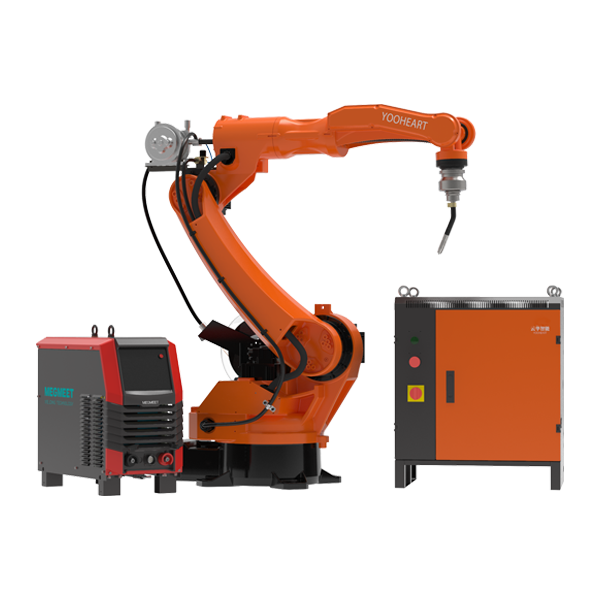

6 Axis Arc welding Robot 1450mm bolelele ba letsoho Ka mohloli oa matla oa ho tjheseletsa oa Megmeet

-'Mele oa roboto: HY1006A-145

-Mohloli oa matla oa weld: Megmeet Ehave CM 350AR

-Torch ea Welding: Loyee gas cooling torch Kapa Honyen Gas cooling torch

-Sefepelo sa terata se nang le rolara ea terata ea 0.8/1.0

-LNC molaoli le Panel

-Ho paka ka Lehong bakeng sa ho romela kantle ho naha

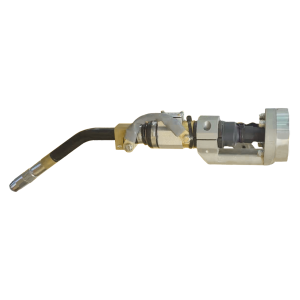

Khetho ea ho Welding Torch

Loyee Robot Welding Torch

Torque e phahameng le cable ea ho hanyetsa

Ho qaptjoa patent ea theknoloji ea Anti-collision

Lebelo le phahameng le ho beha sebaka se nepahetseng sa sesebelisoa se thibelang ho thulana\

Mohala oa mohala: 0.8 ~ 1.0mm

Honyen Robot Welding Torch

Torque e phahameng le cable ea ho hanyetsa

Ho qaptjoa patent ea theknoloji ea Anti-collision

Lebelo le phahameng le ho nepahala ha sesebelisoa se thibelang ho thulana

Mohala oa mohala: 0.8 ~ 1.0mm

Lisebelisoa tse ling tsa Configuration

Megmeet Ehave CM 350AR

| ntho | Tlhaloso |

| Mohlala | Megmeet Ehave CM 350 |

| Palo ea li-volts | 3 * 380V±25% 30--80HZ |

| Rated Input Power | 13.5KVA |

| Ntho ea Matla | 0.94 |

| Katleho | 86% |

| OCV e lekantsoeng | 63.3V |

| Rated Output Current | 30A-400A |

| Rated Output Voltage | 12V-38V |

| Wire Dia | 0.8mm/1.0mm/1.2mm |

| Boemo ba IP | IP23S |

| Sehlopha sa Insulation | H |

| Cooling Mokgwa | Pholiso ea Moea |

| Boemo (L*W*H) | 620mm*300mm*480mm |

| Boima ba 'mele | 48kg |

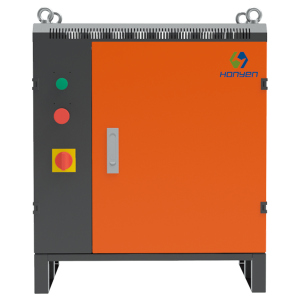

Kabinete ea Taolo

| Ntho | Tlhaloso |

| Boholo ba Kabinete | 603mm*502mm*760mm |

| Boima ba 'mele | 55kg |

| Boemo ba IP | IP54/IP65 |

| Mocheso | Ho sebetsa: 0-45 ℃Sebaka sa polokelo: -10 ~ 60 ℃ |

| Mongobo | Max 90% (Ha ho condensation |

| Palo ea li-volts | 3*380V 50~60HZ |

| Sistimi ea ho Pholisa | Pholiso ea Fane |

| Bolelele ba Cable | Maemo: 5M, Max:12M |

| Mokhoa oa puisano | Pulse |

Sesebelisoa sa terata

Karabelo ka Nako Ho fepa ka terata le ka morao

Ho fepa ka terata ha bonolo, Ho se bokelle le ho thella

Matla a Matla a ho Thibela tšitiso

Kopo ea Moreki

Seteishene sa Mosebetsi sa Roboto ea Kariki ea Bana

Steel Ladder Robot Working Station

Litšoantšo Fekthering ea Bareki

Li-parameter tsa Welding Robot

| Axis | Ho lefa | Pheta-pheta | Matla a matla | Tikoloho | Boima ba 'mele | Ho kenya |

| 6 | 6kg | 0.08 | 6.5KVA | 0 ~ 45℃ 20~80%RH(Ha ho Condensation) | 170kg | Fatše/ Siling |

| Motion Range J1 | J2 | J3 | J4 | J5 | J6 | Boemo ba IP |

| ±170° | +80°~-150° | +95°~-72° | ±170° | +115°~-140° | ±220° | IP54/IP65(letsoho) |

| Lebelo le phahameng J1 | J2 | J3 | J4 | J5 | J6 | |

| 158°/s | 145°/s | 140°/s | 217°/s | 172°/s | 500°/s |

Lipontšo

Beijing Essen Welding & Cutting Fair

Pontšo ea Machabeng ea Indasteri ea Chaena - CIIF

China International Machine Tool Show

FQA

P. Mmaraka oa bohlokoa oa roboto ea hau ke ofe?

A. Hona joale roboto ea rona e ka sebeletsa likoloi, sebopeho sa tšepe, mochini oa polasi, thepa ea ka tlung ea tšepe, matla a macha, polokelo le thomello, mochini oa boenjiniere, lisebelisoa tsa 'mele, mochini oa liphoofolo, baesekele jj.

P. o ka fana ka tshebeletso ya mofuta ofe?

A. Ha e le likopo, ho tjheseletsa, ho fana, ho khetha le ho beha, ho penta, ho penta, ho itšeha ka laser, ho tjheseletsa ka laser, ho itšeha ka plasma joalo-joalo.

Q. U na le mofuta ofe oa ts'ebetso ea welding?

A. Bakeng sa lits'ebetso tsa welding, re ka fana ka welding ea argon arc, welding ea mag, welding ea khase e sireletsang, tig self fusion welding, tig wire feeding welding.

P. Ke mofuta ofe oa mohloli oa matla oo u fanang ka oona bakeng sa roboto?

A. Hona joale bakeng sa tlhophiso e tloaelehileng: Megmeet le AoTai.

P. O na le sistimi ea hau ea taolo?

A. E, ehlile re na le tsona.Hase feela hore re na le tsamaiso ea ho laola, likarolo tsa bohlokoa ka ho fetisisa tsa roboto: reducer e ntse e hlahisoa.Ke kahoo re nang le theko ea tlhōlisano ka ho fetisisa.

Kamora ho rekisa Tšebeletso

Nako ea tiiso ea boleng ba sehlahisoa ke selemo se le seng ho tloha ka letsatsi la ho pepa.Haeba roboto ea ho tjheseletsa e hloleha nakong ea tiisetso (ntle le ho hloleha ho bakoang ke tšebeliso e fosahetseng ea moreki), Honyen Robot e tla ikarabella bakeng sa tlhokomelo ho fihlela e nkela thepa e ncha (EXW), 'me litšenyehelo tse bakiloeng li tla lefelloa ke Honyen(litšenyehelo tsa thomello). ha e kenyelelitsoe);Haeba thepa e hloleha ka lebaka la tšebeliso e fosahetseng ea moreki, feme ea Honyen e tla ikarabella bakeng sa tlhokomelo le tefiso ea likarolo tse ling.

Nakong ea waranti, haeba thepa e hloleha, basebetsi ba litšebeletso tsa tekheniki ba morekisi ba tla lokisa lisebelisoa tse hlokahalang le likarolo tse ling nakong ea lihora tse 8 kamora ho netefatsa ho hloleha ha lisebelisoa le basebetsi ba ts'ebetso le tlhokomelo ea setšeng, 'me ba fihle setšeng nakong ea lihora tse 24. qala tlhokomelo, ho rarolla mathata (ntle le lebaka la sebaka se hole).

Selemo se seng le se seng, ho ipapisitse le maemo a nnete a mmaraka le litlhoko tsa basebelisi ba libaka, k'hamphani e lula e etsa maeto a ho khutla a lits'ebeletso tsa tekheniki mahala (ntle le tefo ea ts'ebeletso ea ho fetola likarolo le likarolo).

Ho tsamaellana le lihlahisoa tse rekisoang ke k'hamphani ea rona le likarolo tse tloaelehileng le likarolo tse ka sebelisoang tsa sete e felletseng ea liroboto tsa welding, re netefatsa ho fana ka lits'ebeletso tse tloaelehileng.Likarolo tse setseng li ka tlung ea polokelo (ntle le lihlahisoa tse khethehileng).Likarolo tse tloaelehileng le likarolo tse sebelisoang li tiisetsoa hore li tla fanoa ka nako ho ea ka taelo, 'me likarolo tse khethehileng li laeloa ho ea ka konteraka e lumellaneng ke mahlakore ka bobeli.

Ka mor'a ho fela ha nako ea tiisetso, haeba thepa e hlōleha, Morekisi o tla tsoelapele ho fana ka litšebeletso tsa tlhokomelo bakeng sa moreki, ho lefisa litšenyehelo tsa ho fetola lisebelisoa, le ho lefisa tefo ea litšebeletso tsa motheo bakeng sa tšebeletso ea ntlo le ntlo.

Ho latela tlhoko ea moreki, Morekisi o tla ikarabella bakeng sa ntlafatso ea bophelo bohle ea mahala ea software e sebelisoang ke moreki bakeng sa roboto ea ho tjheseletsa ea Mig.