Robotic Mig welding ---- Tharollo ea tjheseletsa ea Lebone la Seterateng

Index

1. Boitsebiso ba karolo ea mosebetsi

2. Robotic welding Solution Overview

3. Robotic welding Solution Process

4. Tlhophiso ea Thepa ea Tharollo ea Robotic

5. Mosebetsi o ka Sehloohong 6. Kenyelletso ea Lisebelisoa

7. Tlhophiso, Komisi le Koetliso

8. Hlahloba le Kamohelo

9. Litlhoko tsa Tikoloho

10. Warranty le After sale service

11. Litokomane tse khomaretsoeng tsa thomello

Video ea ts'ebeliso ea liroboto

1, Boitsebiso ba Workpiece

-Welding terata DiameterTlhaloso: Ф1.2mm

-Mokhoa oa ho cheselletsa: welding e sirelelitsoeng ka khase / Mig welding

-Mofuta oa seam oa weld: mofuta oa mola o otlolohileng, mofuta oa selikalikoe

-Ho sireletsa khase:99% CO2

-Mokhoa oa Ts'ebetso: ho kenya le ho laolla ka letsoho, welding ea roboto ka ho iketsa

-Phoso ea ho Lokisa:≤ 0.5mm

-Ho Hloekisa poleiti :metallic luster ka bonoa weld leka har'a mefuta e fapaneng ea bophahamo habeli ba seam weld mahlakoreng ka bobeli

2, Tharollo ea tjheseletsa ea Robotic Overview

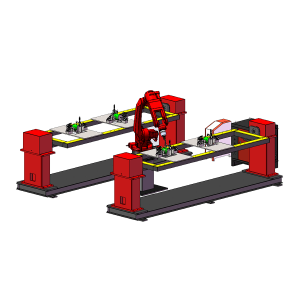

E le ho ntlafatsa katleho ea mosebetsi, ho ea ka boemo ba sebele ba workpiece, fektheri ea Honyen e tla fana ka setsi sa lisebelisoa tsa liroboto tsa welding, tse ka nkeloang sebaka ke lisebelisoa tse fapaneng tsa lisebelisoa hore li lumellane le lihlahisoa tse fapaneng.Setsi sa mosebetsi se entsoe ka mohlala oa liroboto: HY1006A-145 roboto ea ho tjheseletsa, mohloli oa matla a tjheseletsa, toche e khethehileng ea tjheseletsa bakeng sa roboto, Khabinete ea taolo ea motlakase le li-buttons, chiller ea metsi a pholileng, li-positioners tse peli tse sebetsang, lisebelisoa tsa lisebelisoa, terata ea tšireletso ea tšireletso (khetho) le tse ling. dikarolo.

3, Kenyelletso ea sebopeho sa mochini oa liroboto oa Mig Welding

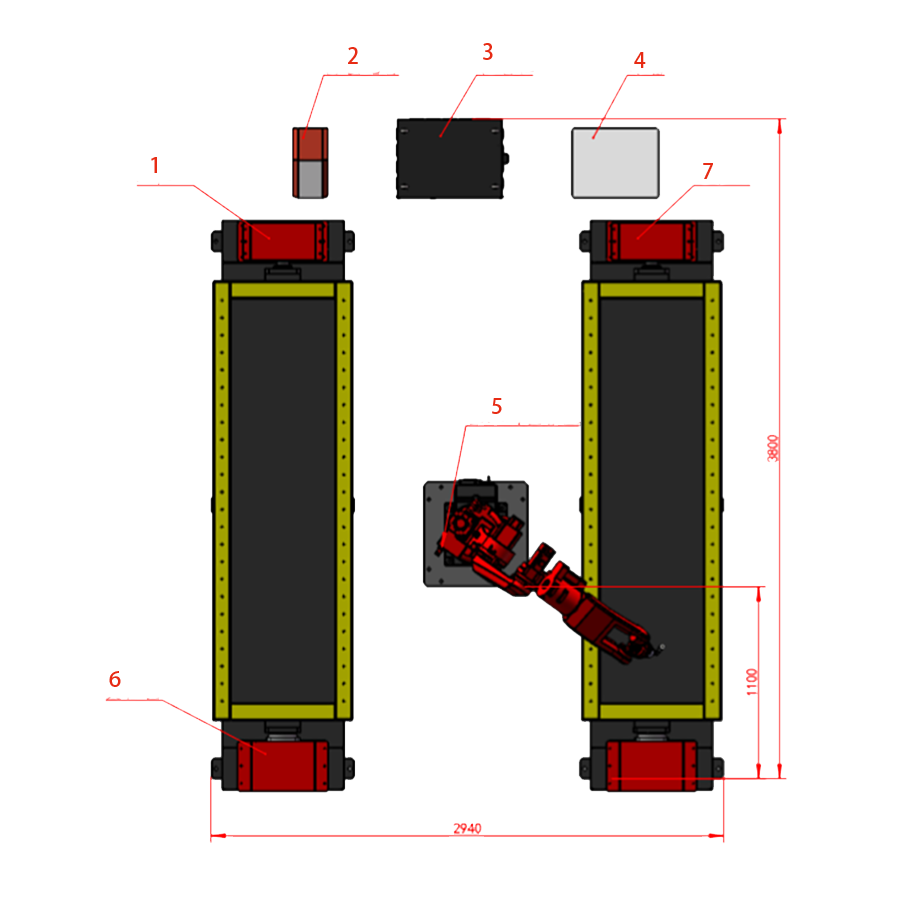

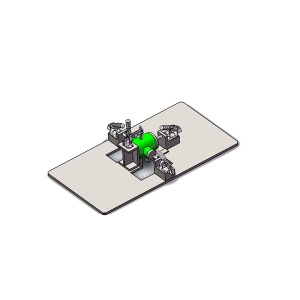

Honyen roboto arc welding workstation Layout

1, Seteishene sa ho sebetsa 1

2, Mohloli oa Welding Power

3, molaoli oa liroboto

4, Sehatsetsi sa ho futhumatsa metsi

5, Honyen arc welding Robot, HY1006A-145

6, Sebaka

7, Seteishene sa ho sebetsa 2

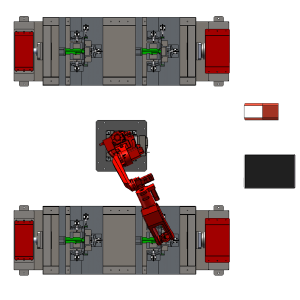

Lisebelisoa tsa likarolo tsa motlakase

Lisebelisoa tsa likarolo tsa motlakase 2

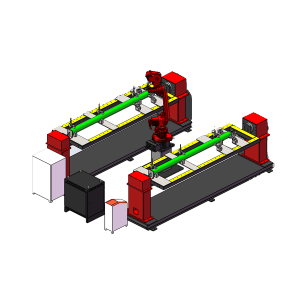

Litharollo tsa liroboto tsa welding Sebopeho sa 1

Likarolo tsa likarolo tsa lipalo tsa Motlakase 3

Litharollo tsa liroboto tsa welding Sebopeho sa 2

Litharollo tsa liroboto tsa welding Sebopeho sa 3

4. Robotic welding Solution Process I. Opereishene e jara workpiece seteisheneng sa 1, Ka mor'a ho e kenya le ho e koala.Opereishene e tobetsa konopo ea 1 ea ho beha liroboto, ebe roboto e qala ho tjheseletsa ka boiketsetso;

II.Opereishene e ea seteisheneng sa 2 bakeng sa ho kenya lisebelisoa tsa mosebetsi.Ka mor'a ho kenya mosebetsi, Opereishene e tobetsa konopo ea 2 ea pehelo ea roboto ebe e emela hore roboto e qete ho tjheseletsa;

III.Ka mor'a hore roboto e qete ho cheselletsa seteisheneng sa 1, e iketsetsa lenaneo la seteishene sa 2;

Ⅳ.Ebe Operator e laolla Workpiece seteisheneng sa 1 ebe e jarisa sesebediswa se secha;

V. potoloho ka tatellano.

5. Tlhophiso ea Thepa ea Tharollo ea Robotic

| Ntho | Mohlala | Bongata | Brand | Litlhaloso | ||

| 1 | 1.1 | 'Mele oa roboto | HY1006A-145 | 1 Sete | Honyen | Ho kenyeletsoa 'mele oa liroboto, khabinete ea taolo, moqapi oa thuto |

| 1.2 | Khabinete ea taolo ea liroboto | 1 sete | ||||

| 1.3 | Mohloli oa matla a ho cheselletsa | 1 Sete | Honyen | Megmeet welder | ||

| 1.4 | tanka ea metsi | 1 Sete | Honyen | |||

| 1.5 | Metsi a pholileng a cheseletsa Toche | 1 Sete | Honyen | |||

| 2 | 1 Axis positioner | HY4030 | 2 Seta | Honyen | 2.5m, mojaro oa 300kg, matla a hlahisoang ke 1.5KW | |

| 3 | Seteishene sa taolo ea motlakase | 2 Seta | Honyen | |||

| 4 | Moralo oa sistimi, kopanyo le mananeo | 1 Sete | Honyen | |||

| 5 | Lekhoakhoa la tšireletso | 1 Sete | Honyen | Taba ea boikhethelo | ||

6. Mosebetsi o ka Sehloohong Bakeng sa ho netefatsa boleng le ts'ebetso ea welding, sistimi ea liroboto e na le ts'ebetso e phethahetseng ea ho itšireletsa le polokelo ea polokelo ea li-arc.Mesebetsi ea mantlha ke e latelang:

Tsoela pele ka tsela ea pele: ha thebe phallo ea khase ke ntho e sa tloaelehang, tjheseletsa terata chesa 'me ka nakoana emisoa nakong tjheseletsa, taelo ea "tsoela pele tjheseletsa" ka ka ho toba bitsoa ka mor'a ho rarolla mathata, le roboto ka tsela e iketsang tsoela pele ho tjheseletsa ho tloha boemong leha e le efe ho boemo emisitsoe.

Ho lemoha liphoso le ho bolela esale pele: ka mor'a hore alamo e hlahe, Robot e fumana data ho tswa ho sesebelisoa sa taolo, ho hakanya likarolo tsa phoso, 'me e fane ka lethathamo la likarolo tse phahameng ka lehlakoreng le leng, e bonts'a tatellano ea likarolo tse ncha le ho hlahlojoa k'homphieutheng, e ka bonoang sebakeng sa marang-rang ka pendant ea ho ruta.Ntle le moo, komporo khafetsa Fumana lintlha tsa ts'ebetso ho tsoa ho roboto, sekaseka lintlha tse fumanoeng, ahlola hore na boemo ba roboto bo tloaelehile, 'me u potlakele mosebelisi ho sebetsana le phoso e tlang.

Mosebetsi oa ho thibela ho thulana: ha roboto e cheseletsa toche e etsa ho soahlamana le lintho tse ka ntle, sesebelisoa sa roboto se thibelang ho thulana se sebetsa ho sireletsa tjheseletsa Torch le 'mele oa roboto.

Setsebi polokelongtshedimosetso: Ka ho beha maemo a hlokahalang bakeng sa tjheseletsa lenaneong, tsamaiso ena e ka iketsetsa tlhophiso ea seam ea weld le tokiso ea li-parameter tse tsamaisanang le welding.

Ho ruta le ho etsa mananeo: hlokomela mananeo a sebakeng sa marang-rang ka ho ruta pendant.

Weave welding: nakong tjheseletsa tshebetso, Robot ke ke feela hlokomela tloaelehileng swing tjheseletsa pota mofuta le Hape mofuta Z.Sena se thusa roboto ho hlokomela ts'ebetso ea moreki ea swing welding ho latela sebopeho sa sekhechana sa mosebetsi, e le ho eketsa bophara ba seam sa weld ka matla a welding le ts'ebetso e ntle ea welding.

Pontšo ea boemo: roboto e ka bonts'a boemo ba ts'ebetso ea sistimi eohle ea liroboto ka pendant ea ho ruta, ho kenyelletsa boemo ba ts'ebetso ea lenaneo, liphetoho tsa paramethara ea welding, liphetoho tsa parameter ea sistimi, boemo ba hajoale ba roboto, lirekoto tsa nalane ea ts'ebetso, matšoao a polokeho, lirekoto tsa alamo, jj. utloisisa boemo ba tsamaiso ea liroboto ka nako le ho thibela mathata esale pele.

Lifaele tse kentsoeng / tse hlahisoang: Lifaele tsa tsamaiso ea liroboto le lifaele tsa lenaneo tsamaisong ea liroboto li ka bolokoa ka karete ea SD ka har'a taolo ea roboto, hape li ka bolokoa lisebelisoa tsa kantle.Mananeo a ngotsoeng ke software ea offline programming a ka boela a kenngoa ho Robot controller, Sena se thusa bareki ho boloka lifaele tsa tsamaiso kamehla, Hang ha ho na le bothata tsamaisong ea liroboto, Backup ena e ka tsosolosoa ho rarolla mathata a roboto.

7, Kenyelletso ea Lisebelisoa HY1006A-145 ke roboto ea ts'ebetso e phahameng e nang le ts'ebetso e bohlale.E loketse bakeng sa ts'ebeliso ea li-welding tse sirelelitsoeng ka khase le ho itšeha.Litšobotsi tsa eona ke boima bo bobebe le sebopeho se kopaneng.

Bakeng sa lits'ebetso tsa welding tsa arc, Honyen e atlehile ho etsa boima bo bobebe le letsoho le kopaneng, le sa netefatseng feela ts'epo ea mantlha, hape e hlokomela ts'ebetso e ntle ea litšenyehelo.

Honyen e sebelisa theknoloji ea servo e tsoetseng pele ka ho fetesisa, e ka ntlafatsang lebelo la ho sisinyeha le ho nepahala ha liroboto, ea fokotsa ho kenella ha opereishene, le ho ntlafatsa ts'ebetso ea ts'ebetso ea ts'ebetso ea ho cheselletsa le ho itšeha ka khase.

| Axis | Ho lefa | Pheta-pheta | Matla a matla | Tikoloho | Boima ba 'mele | Ho kenya |

| 6 | 10 | 0.08 | 6.5KVA | 0~45℃20~80%RH(Ha ho Mongobo) | 300kg | Fatše/ Siling |

| Motion Range J1 | J2 | J3 | J4 | J5 | J6 | Boemo ba IP |

| ±170° | +80°~-150° | +95°~-72° | ±170° | +115°~-140° | ±220° | IP54/IP65(letsoho) |

| Lebelo le phahameng J1 | J2 | J3 | J4 | J5 | J6 | |

| 158°/s | 145°/s | 140°/s | 217°/s | 172°/s | 500°/s |

Sebopeho se felletseng sa ts'ebetso ea Sechaena 'me se ka fetoleloa ho Senyesemane ka ts'ebetso e felletseng ea keyboard

Ts'ehetsa likhokahano tse fapaneng ho kenyelletsa segokanyimmediamentsi sa I / O, Modbus, Ethernet jj.

Ts'ehetsa likhokahano le liroboto tse ngata le lisebelisoa tse ling tsa kantle

Skrine se seholo sa ho thetsa se mebala-bala

Sesebelisoa se lokiselitsoeng se thibelang ho thulana, se sireletsang letsoho la roboto le ho fokotsa tšitiso

Taolo ea Motion ea Robot e fana ka moralo o nepahetseng oa tsela

Makholo a makholo a mekotla e kentsoeng kahare le mesebetsi e nolofatsa mananeo

Ka karete ea SD, ho bonolo ho boloka le ho kopitsa data

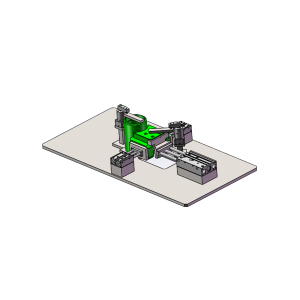

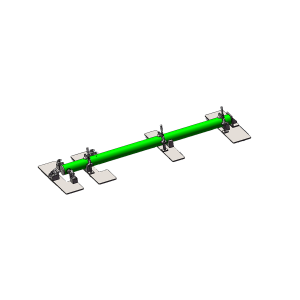

Sebaka

Honyen Head-tail double support positioner e sebelisetsoang ho potoloha workpiece, ho sebelisana le roboto, ho fihla boemong bo botle ba ho tjheseletsa le ho finyella tshebetso e ntle ya welding.

Mohloli oa Welding Power

Megmeet Ehave cm 500h / 500 / 350 letoto le felletseng la moroalo o boima oa indasteri ea dijithale * CO2 / MAG / MMA mochini o tjheseletsang o bohlale

8. Tlhophiso, Komisi le Koetliso

Pele ho pepa, sistimi ea liroboto e tla bokelloa mme e lekoe ka botlalo k'hamphaning ea rona.Moreki o tla isa likarolo tsa bona k'hamphaning ea rona bakeng sa welding ea liteko le ho amoheloa pele pele ho tlisoa.Nakong ea kamohelo ea pele, basebetsi ba Bareki ba tla fumana koetliso ea pele ea tekheniki.

Moralo oa ho kenya le litlhoko tsa tekheniki li tla romelloa ho moreki matsatsi a 15 pele a kenya, 'me moreki o tla etsa litokisetso tse nakong ho latela litlhoko.Khamphani ea rona e tla romella lienjineri ho kenya tšebetsong le ho kenya sistimi sebakeng sa mosebelisi.Tlas'a maemo a hore moreki a netefatsa li-workpieces tse lekaneng, nako ea ho tloha ho komisi ea mananeo, koetliso ea basebetsi ho isa tlhahiso ea liteko tse ngata e ke ke ea feta matsatsi a 10.Khamphani ea rona e koetlisa basebelisi ba mananeo a liroboto, ts'ebetso le tlhokomelo bakeng sa bareki, mme baithuti ba lokela ho ba le tsebo ea mantlha ea komporo.

Nakong ea ho kenya le ho laela, moreki o tla fana ka lisebelisoa tse hlokahalang, tse kang lisebelisoa tsa ho phahamisa, forklift, cables, drill drill, joalo-joalo, le ho fana ka thuso ea nakoana nakong ea ho laolla le ho kenya.

Khamphani ea rona e ikarabella bakeng sa tataiso, ho kenya, ho laela lisebelisoa le koetliso ea opareitara.Khamphani ea rona e ikarabella bakeng sa koetliso ea tlhokomelo le ts'ebetso.Opereishene e tla sebetsa le ho hlokomela lisebelisoa ka botsona.Likahare tsa koetliso: molao-motheo oa sebopeho sa lisebelisoa, ho rarolla mathata a motlakase a tloaelehileng, kenyelletso ea litaelo tsa motheo tsa lenaneo, litsebo tsa lenaneo le mekhoa ea mananeo a likarolo tse tloaelehileng, selelekela le litemoso tsa phanele ea ts'ebetso ea lisebelisoa, ts'ebetso ea ts'ebetso ea lisebelisoa, joalo-joalo.

9. Hlahloba le ho amohela

Kamohelo ea pele e etsoa k'hamphaning ea rona ka ho nka karolo ha basebetsi ba amehang ba mahlakore ka bobeli.Nakong ea ho amoheloa pele, li-workpiece li tla lekoa ho latela ho nepahala ha workpiece e fanoeng ke moreki, Ke sekhechana sa mosebetsi se tšoanelehang feela se tla kenngoa, 'me ho tla fanoa ka tlaleho ea tlhahlobo ea pele ho kamohelo.Kamora ho amoheloa ka botlalo, Roboto e tla tsamaisoa.E le ho netefatsa ho amoheloa pele, li-workpieces tse 3 li tla fanoa bakeng sa tlhahiso e tloaelehileng.

10.Litlhoko tsa Tikoloho Litlhoko tsa polokeho: khase le likarolo tse ling tse sebelisoang ke basebelisi li tlameha ho latela maemo a naha a amehang.

Mohloli oa moea o tla beoa kantle, eseng ka tlase ho 15m hole le mollo, 'me e seng ka tlase ho 15m hole le khase le oksijene.Mohloli oa moea o tla boloka maemo a matle a moea 'me o be sebakeng se phodileng hole le moea.

Lipotoloho tsohle tsa khase li tlameha ho hlahlojoa pele li sebelisa roboto.Haeba ho na le ho lutla ha moea, ho tlameha ho lokisoa ho netefatsa hore ha ho phoso.

ha o lokisa khatello le ho fetola moqomo oa khase, mosebeletsi ha a na ho ba le lintho tsa oli matsohong a hae.

mongobo oa tikoloho: ka kakaretso, mongobo o teng ke 20% ~ 75% RH (haeba ho se na condensation);Nako e khutšoanyane (ka khoeli ea 1) ka tlase ho 95% RH (ka linako tse ling ntle le condensation).

moea o hatelitsoeng: 4.5 ~ 6.0 kgf / cm2 (0.45-0.6mpa), sefa oli le metsi, ≥ 100L / min

Motheo: bonyane matla a konkreite ke C25, 'me bonyane botenya ba motheo ke 400 mm

vibration/ Ketso ya ho thothomela: ho ba hole le mohlodi wa thothomelo

phepelo ea motlakase: phepelo ea motlakase ea lisebelisoa tsohle tse entsoeng tsa motlakase le tsa elektroniki e nka 50Hz (± 1) le 380V (± 10%) motlakase oa mekhahlelo e meraro ea AC ho etsa bonnete ba hore phepelo ea motlakase e qala.

Litšebeletso tsa marang-rang tse fanoang ke bareki:

litokisetso tsohle tse hlokahalang pele ho pepa, joalo ka motheo, mosebetsi o hlokahalang oa ho tjheseletsa, ho lokisa lisebelisoa tse thusang, joalo-joalo.

ho laolla le ho tsamaisa setsheng sa moreki.

11. Warranty le After sale service Nako ea tiisetso ea mohloli oa matla a weld ke likhoeli tse 12.

Nako ea tiisetso ea 'mele oa roboto ke likhoeli tse 18.

Haeba ho hloleha kapa ho senyehile tlas'a ts'ebeliso e tloaelehileng 'me thepa e ka har'a nako ea tiisetso, k'hamphani ea rona e ka lokisa kapa ea nkela likarolo tsa eona mahala EXW (ntle le lisebelisoa, lihlahisoa tsa tlhokomelo, li-tubes tsa polokeho, mabone a matšoao le lisebelisoa tse ling tse khethiloeng ka ho khetheha ke k'hamphani ea rona).

Bakeng sa likarolo tse tlokotsing ntle le waranti, k'hamphani ea rona e tšepisa bophelo bo tloaelehileng ba tšebeletso le theko ea phepelo ea likarolo tse tlokotsing, 'me lisebelisoa li na le mocha o tsitsitseng oa thepa ho fihlela lilemo tse hlano.

Kamora nako ea waranti, k'hamphani ea rona e tla tsoelapele ho fana ka ts'ebeletso e lefuoang bophelo bohle le ho fana ka tšehetso e felletseng ea tekheniki le lisebelisoa tse hlokahalang.

12. Delivery Attached Documentation Litšoantšo tsa ho kenya: litšoantšo tsa kaho ea motheo oa lisebelisoa le litšoantšo tsa ho kenya lisebelisoa

◆ litšoantšo tsa moralo: litšoantšo le lisebelisoa tsa thepa

◆ Bukana: buka ea ts'ebetso ea lisebelisoa, buka ea tlhokomelo le buka ea ts'ebetso ea roboto

◆ lisebelisoa: lethathamo la thepa, setifikeiti le karete ea tiisetso.