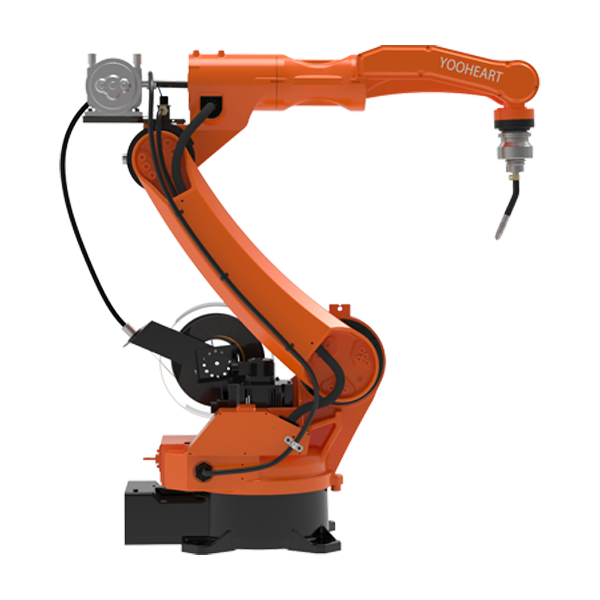

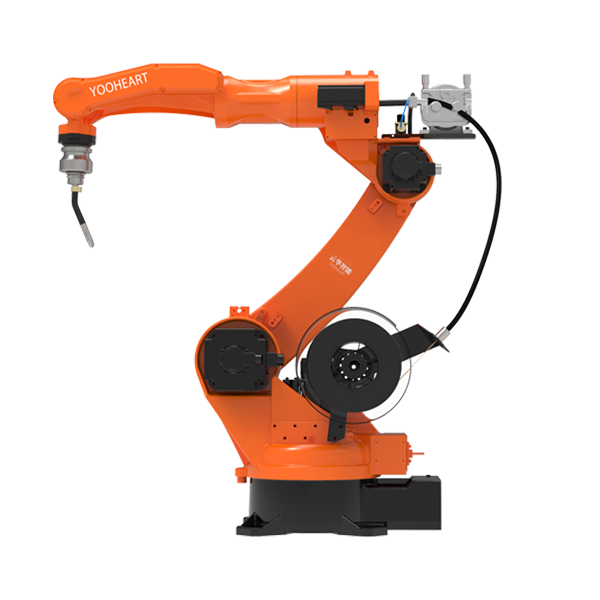

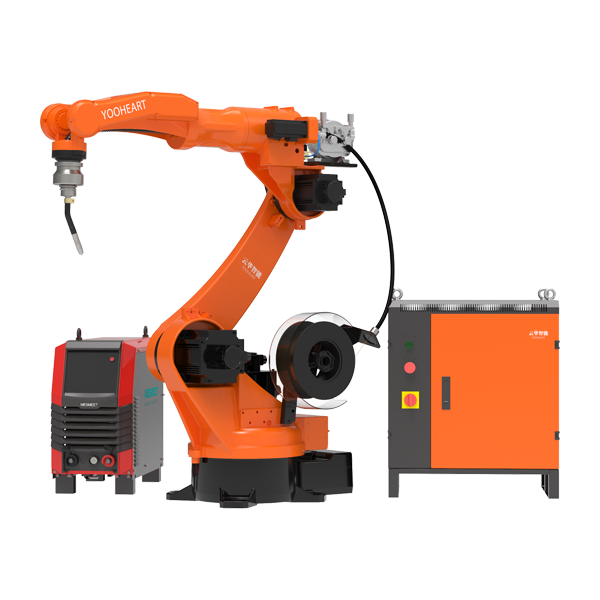

6 axis Mig welding roboto bakeng sa raka ea polokelo

Kenyelletso ea Sehlahisoa

Roboto ea li-axis welding ke e 'ngoe ea liroboto tse tloaelehileng tsa sehlahisoa sa Yooheart.Joalo ka ha le tseba, ho feta 50% ea thepa e hlokahalang ho cheselletsa ke tšepe ea carbon, kahoo molemong oa ho cheselletsa tšepe ea khabone hantle, ho na le meralo e mengata e ikhethang bakeng sa roboto ea li-axis tse tšeletseng.Ho na le li-unit tse fetang 5000 tse ileng tsa rekisoa Chaena ka selemo ka lebaka la botsitso le ho tšoarella ha eona.

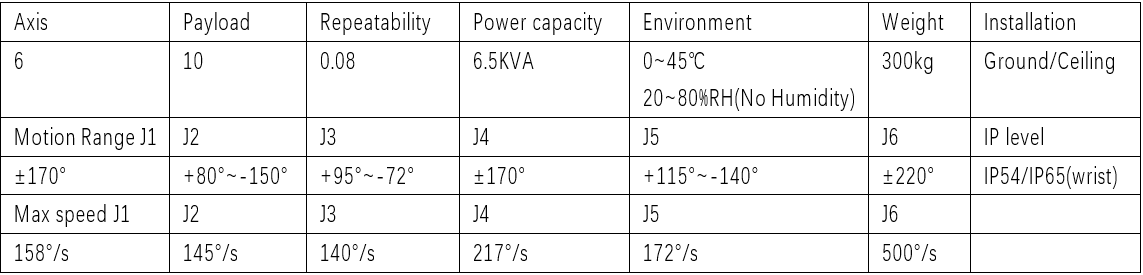

PRODUCT PARAMETER & DINTLHA

Joalo ka e 'ngoe ea liroboto tse tsebahalang tsa liindasteri, e na le letsoho le bonolo le tšitiso ea metsotso le maemo a feto-fetohang, motlakase oa hona joale oa welding le phepelo ea terata li ka laoloa ka nako ea nnete.Mekhahlelo ea welding ea mohala oa welding e ka beoa ka kotloloho holim'a pendant ea ho ruta ea roboto.

Kopo

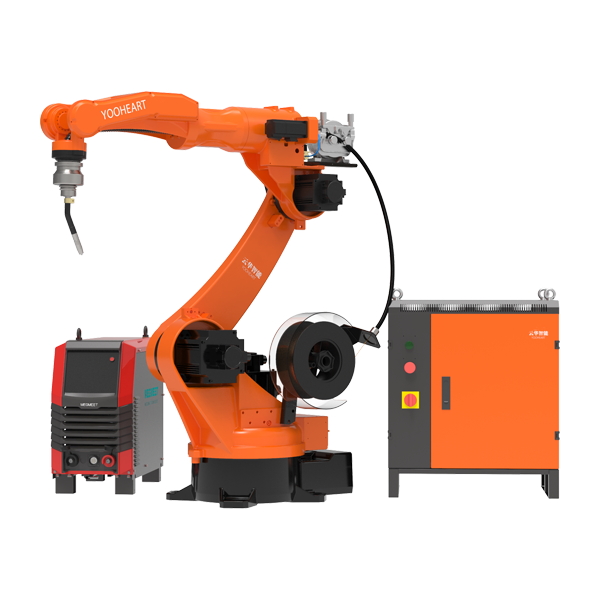

SETŠOANTŠO 1

Selelekela

Synergy ea liroboto e nang le sebaka se le seng sa axis

Setšoantšong sena, moreki oa rona o sebelisa 2000mm fihla roboto hokela tse peli 1 axis positioner

Roboto e tla lula e cheselletsa ha basebetsi ba kenya sekhechana sa mosebetsi sebakeng se le seng.

Ka tsela ena, fokotsa litšenyehelo le ho phahamisa tlhahiso.

SETŠOANTŠO 2

Selelekela

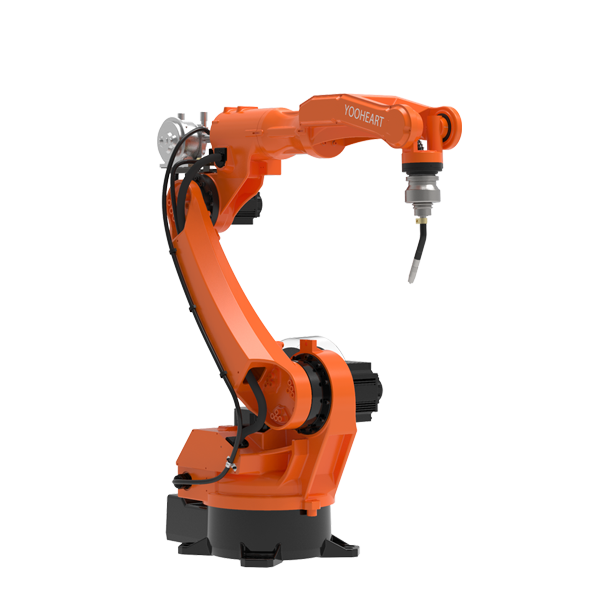

Robot e bolelele ba 2000mm

Setšoantšo se ka ho le letona se bonts'a terata ea rona ea 2meter e fihlang ho roboto ea liphoofolo.

karolo ea ho sebetsa ke phala e sekoere, Customer sebelisa Aotai 350A welder e nang le ts'ebetso e tlase ea spatters.

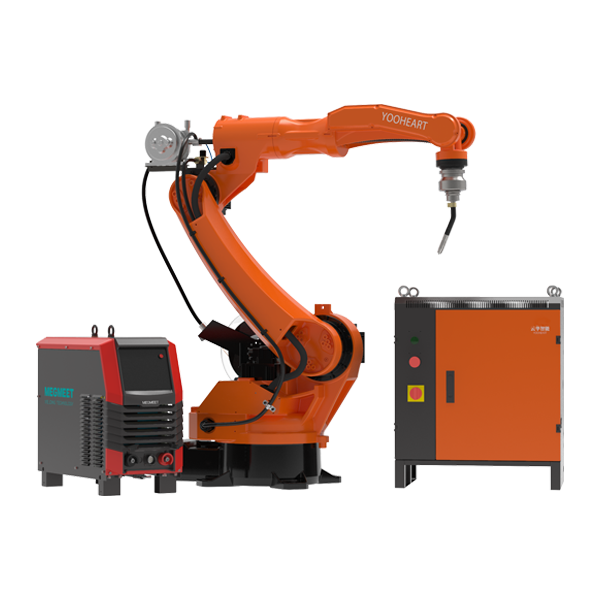

SETŠOANTŠO 3

Selelekela

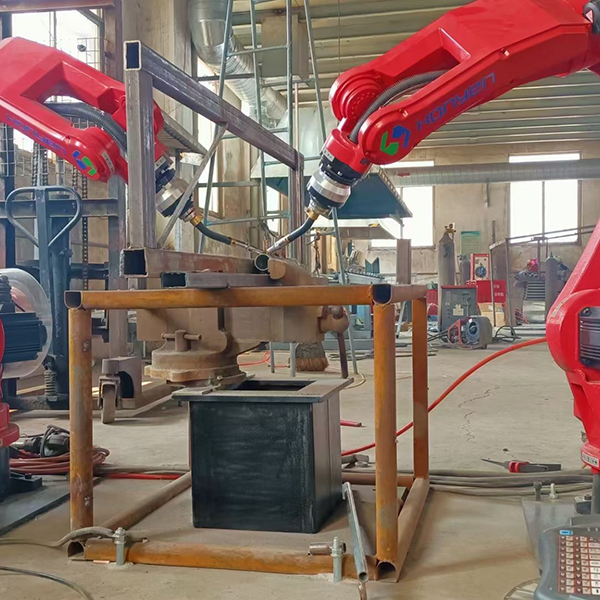

Liroboto tse peli tse sebetsang hammoho

Litšoantšo tse ka ho le letšehali li bonts'a likamano tse peli tsa liroboto tsa Yooheart hammoho.

E le ho phahamisa lebelo la ho tjheseletsa, le ho rarolla bothata ba boemo ba ho tjheseletsa (ka linako tse ling roboto e le 'ngoe e tla kopana le bothata ba boemo ba torch), ho tla kenngoa liroboto tse peli tsa welding.

PHELISO LE THUSO

Khamphani ea Yunhua e ka fana ka bareki ka maemo a fapaneng a ho tsamaisa.Bareki ba ka khetha ho tsamaisoa ka sekepe ka leoatle kapa ka sefofane ho latela maemo a pele a potlakileng.Likotlolo tsa liphutheloana tsa YOOHEART li ka kopana le tlhokahalo ea thepa ea leoatle le moea.Re tla lokisa lifaele tsohle joalo ka PL, setifikeiti sa tšimoloho, invoice le lifaele tse ling.Ho na le mosebeletsi eo mosebetsi oa hae o ka sehloohong e leng ho etsa bonnete ba hore roboto e 'ngoe le e' ngoe e ka isoa boema-kepe ba bareki ntle le ho ts'oaroa matsatsing a 40 a ts'ebetso.

Ka mor'a tšebeletso ea thekiso

Moreki e mong le e mong o lokela ho tseba roboto ea YOO HEART pele a e reka.Hang ha bareki ba e-na le roboto e le 'ngoe ea YOO HEART, mosebeletsi oa bona o tla ba le koetliso ea mahala ea matsatsi a 3-5 fekthering ea YOO HEART.Ho tla ba le sehlopha sa wechat kapa whatsapp, litheknishiene tsa rona tse ikarabellang ka mor'a ho rekisa tšebeletso, motlakase, hard ware, software, joalo-joalo li tla ba teng. Haeba bothata bo le bong bo ka etsahala habeli, setsebi sa rona se tla ea k'hamphaning ea bareki ho rarolla bothata. .

FQA

Q1.Roboto ea YOO HEART e ka eketsa li-axis tse kae tsa kantle?

A.Hajoale, roboto ea YOO HEART e ka eketsa 3 axis ea kantle ho roboto e ka sebelisanang le roboto.Ka mantsoe a mang, re na le seteishene sa mosebetsi sa liroboto se tloaelehileng se nang le 7 axis, 8 axis le 9 axis.

Q2.Haeba re batla ho eketsa axis ho roboto, na ho na le khetho?

A. Na u tseba PLC?Haeba u tseba sena, roboto ea rona e ka buisana le PLC, ebe e fana ka matšoao ho PLC ho laola axis e ka ntle.Ka tsela ena, o ka eketsa li-axis tse 10 kapa ho feta.Khaello feela ea tsela ena ke hore axis e kantle e ke ke ea sebelisana le roboto.

Q3.PLC e buisana joang le roboto?

A. Re na le boto ea i / O ka har'a khabinete ea taolo, ho na le 22 port port le 22 input port, PLC e tla hokahanya boto ea I / O le ho amohela lipontšo ho tsoa ho roboto.

Q4.A na re ka eketsa boema-kepe ba I/o?

K. Bakeng sa ts'ebetso ea weld habonolo, li-port tsena tsa I/O li lekane, haeba u hloka tse ling, re na le I/O e atolosang board.O ka eketsa tse ling tse 22 le tlhahiso.

Q5.U sebelisa PLC ea mofuta ofe?

A. Hona joale re ka hokahanya Mitsubishi le Siemens le mefuta e meng.