Bingo MIG mochini o tjheseletsang

Re Lebele Ka Liketso!

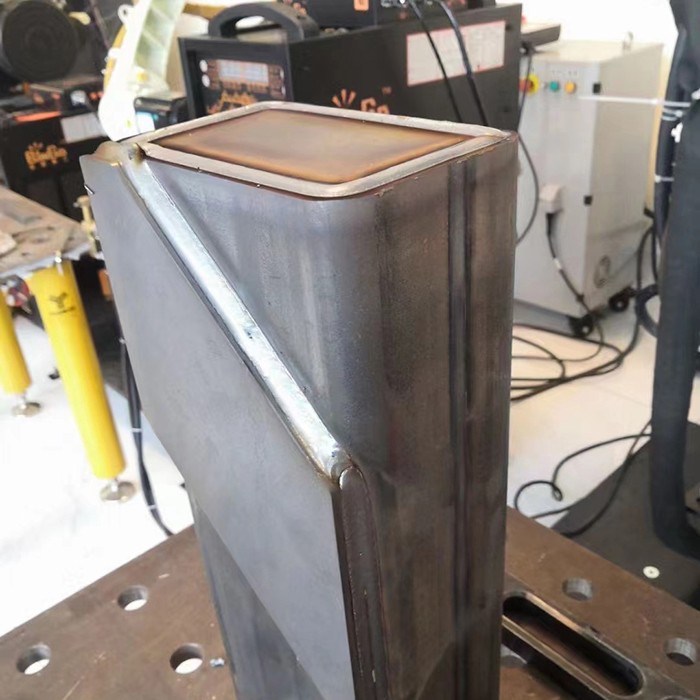

Ts'ebetso ea Welding

Sepheo sa rona ke ts'ebetso e ntle feela ea welding

Mohlala o Tummeng o Latelang

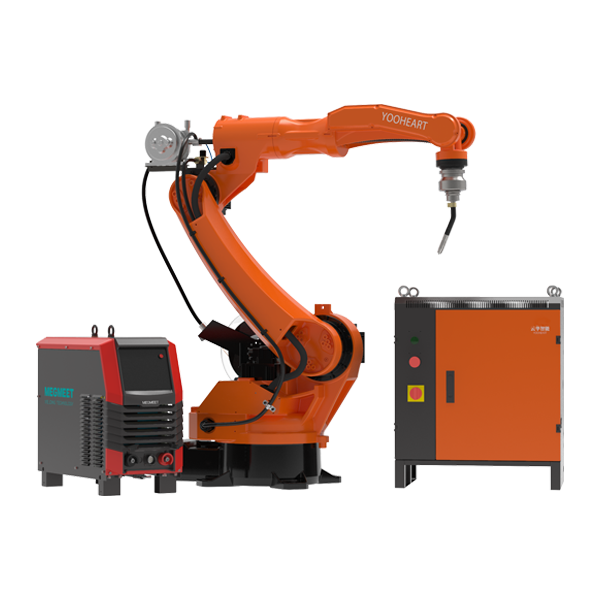

Mohloli oa matla oa MIG, Moetso oa Manual&Robot, Tšehetsa protocal e fapaneng ea puisano

Pulse MIG/MAG 350/500IX

Mono-pulse Mono-pulse MIG/MAG Gas Shielded Shielded Machine

Motlakase oa kamehla oa MIG/MAG

Tšusumetso ea MIG/MAG Mesebetsi:

Impulse MIG/MAG, kakaretso MIG/MAG.

Indasteri ea likopo:

Terene e lebelo, sekepe sa khatello, ho paka koloi hape, yacht, matla a phahamengswitjha le karohano ya sebaka.

Likaroloana:

◆CPU + DSP e feletseng ea digital high-precision control system e laola ka mokhoa o nepahetseng sebopeho sa maqhubu 'me se hlokomela phetoho e phethahetseng ea lerotholi le le leng ka sekhahla, ka arc e tsitsitseng ea welding, spatter e ka tlaase, ponahalo e ntle ea weld le boleng bo phahameng ba welding;

◆ Sebaka sa polokelo ea litsebi se hahelletsoeng ka hare se kenyelletsa lintlha tse nepahetseng tsa taolo ea li-welding waveform, litekanyetso tsa ts'ebetso ea welding le li-arc striking and suppression parameters.Ho bonolo ho fetola liparamente le ho ipapisa le liparamente tse nepahetseng;

◆ Phetoho e kopaneng / e arohaneng e loketse ho kopana le mekhoa e fapaneng ea ho sebelisa;

◆ Ho na le mekhoa e mene ea ts'ebetso ea mehato e 'meli, mehato e mene, e khethehileng ea mehato e mene le ho cheselletsa matheba.Ho tjheseletsa tse kgololitlhaloso tse telele tsa li-welding seams, mehato e mene kapa e khethehileng ea mehato e mene e fokotsa matla a basebetsi ba li-welders.le ho ntlafatsa boleng ba tjheseletsa lenonyeletso;

◆E kopana ka potlako le litlhoko tsa basebelisi bakeng sa ts'ebetso e khethehileng ea tjheseletsa.Mokhoa o felletseng oa taolo ea dijithale o ka fihlela litlhoko tse ikhethang ka ho fetola le ho ntlafatsa software, ntle le ho fetola hardware;

Litekanyetso tsa tekheniki

| Mohlala | Pulse MIG-350IX | Pulse MIG-500IX |

| E lekanyelitsoe matla a motlakase / maqhubu | Mekhahlelo e meraro380V (+/-) 10% 50Hz | |

| E reitiloe matla a ho kenya (KVA) | 17.1 | 27.6 |

| Lintlha tse kentsoeng hajoale (A) | 26 | 42 |

| Reted output voltage (V) | 31.5 | 39 |

| E lekanyelitsoe ho tšoarella ha mojaro (%) | 100 | 100 |

| Motlakase o sa keneng motlakase (V) | 85 | 85 |

| Sephetho sa hajoale (A) | 20 ~ 350 | 20 ~ 500 |

| Mofuta oa motlakase o tsoang (V) | 14-40 | 14-50 |

| Bophara ba terata e chesellang (mm) | 0.8, 1.0, 1.2 | 0.8, 1.0, 1.2, 1.6 |

| Mofuta oa terata ea welding | Litšobotsi tsa Pulse Tšipe e tiileng ea k'habone / tšepe ea k'habone e nang le mantlha ea lik'hemik'hale, tšepe e sa hloekang e tiileng / tšepe e sa hloekang e nang le motsoako oa lik'hemik'hale, koporo le alloy ea koporo. | |

| Constant voltage character CO2 carbon steel, carbon steel, carbon steel, carbon steel e nang le k'hemik'hale ea mantlha ea tšepe e sa hloekang e tiileng / tšepe e sa hloekang e nang le lik'hemik'hale, koporo le motsoako oa koporo. | ||

| Mofuta oa ho fepa ka terata | Sututsa (hla-hla-la) /push-hu-la | |

| Phallo ea khase (L/min) | 15-20 | |

| Mokhoa oa ho pholisa | Phodiso ya metsi / Phodiso ya moya | |

| Sehlopha sa tšireletso ea likhetla | IP21S | |

| Boemo ba ho itšireletsa | H/B | |

Pulse MIG/MAG350/500II

Mochini oa tjheseletsa oa thebe ea khase oa MIG/MAG o kentsoeng habeli

MMA CAC-A MIG/MAG

Manual mental Gouging Impulse

ho tjheseletsa arc

MIG/MAG TIG

Kamehla

motlakase oa hona joale oa DC / AC

Mesebetsi:

Impulse MIG/MAG, kakaretso MIG/MAG, tšepe-arc tjheseletsa, ho phahamisa arc e otlang TIG le gouging.

Indasteri ea likopo:

Terene e lebelo le phahameng, sekepe sa khatello, ho paka koloi hape, yacht, switch ea motlakase o phahameng le karolo ea sebaka.

Likaroloana:

◆CPU + DSP e feletseng ea digital high-precision control system e laola ka mokhoa o nepahetseng sebopeho sa maqhubu 'me se hlokomela phetoho e phethahetseng ea lerotholi le le leng ka sekhahla, ka arc e tsitsitseng ea welding, spatter e ka tlaase, ponahalo e ntle ea weld le boleng bo phahameng ba welding;

◆ Sebaka sa polokelo ea litsebi se hahelletsoeng ka hare se kenyelletsa lintlha tse nepahetseng tsa taolo ea li-welding waveform, litekanyetso tsa ts'ebetso ea welding le li-arc striking and suppression parameters.Ho bonolo ho fetola liparamente le ho ipapisa le liparamente tse nepahetseng;

◆ Thepa e felletseng ea dijithale ea CPU e laola mokhoa o phahameng oa taolo ea terata le sesebelisoa sa taolo ea dijithale tse peli le tse peli tse khannoang tse peli tsa phepelo ea terata e nang le encoder e netefatsa phepelo e tsitsitseng ea terata ha mojaro oa phepelo ea terata o fetoha kapa motlakase oa net. e feto-fetoha ha ho etsoa welding;

◆ Phetoho e kopaneng / e arohaneng e loketse ho kopana le mekhoa e fapaneng ea ho sebelisa;

◆ E na le mekhoa e mene ea ts'ebetso ea mehato e 'meli, mehato e mene, e khethehileng ea mehato e mene le ho cheselletsa letheba.Ho tjheseletsa ha seams se seholo sa nako e telele, mehato e mene kapa e khethehileng ea mehato e mene e fokotsa matla a mosebetsi oa li-welders le ho ntlafatsa boleng ba motsoako oa ho cheselletsa;

◆E kopana ka potlako le litlhoko tsa basebelisi bakeng sa ts'ebetso e khethehileng ea tjheseletsa.Mokhoa o felletseng oa taolo ea dijithale o ka fihlela litlhoko tse ikhethang ka ho fetola le ho ntlafatsa software, ntle le ho fetola hardware;

Litekanyetso tsa tekheniki

| Mohlala | Pulse MIG-350II | Pulse MIG-500II |

| E lekanyelitsoe matla a motlakase / maqhubu | Mekhahlelo e meraro380V (+/-) 10% 50Hz | |

| E reitiloe matla a ho kenya (KVA) | 17.1 | 27.6 |

| Lintlha tse kentsoeng hajoale (A) | 26 | 42 |

| Reted output voltage (V) | 31.5 | 39 |

| E lekanyelitsoe ho tšoarella ha mojaro (%) | 60 | 60 |

| Motlakase o sa keneng motlakase (V) | 85 | 85 |

| Sephetho sa hajoale (A) | 20 ~ 350 | 20 ~ 500 |

| Mofuta oa motlakase o tsoang (V) | 14-40 | 14-50 |

| Bophara ba terata e chesellang (mm) | 0.8, 1.0, 1.2 | 0.8, 1.0, 1.2, 1.6, 2.0 |

| Mofuta oa terata ea welding | Litšobotsi tsa Pulse Tšepe ea carbon e tiileng / tšepe ea carbon e nang le lik'hemik'hale, tšepe e sa hloekang e tiileng / tšepe e sa hloekang e nang le lik'hemik'hale tsa Al-Mg alloy, aluminium e hloekileng le Al-Si alloy, koporo le motsoako oa koporo. | |

| Constant voltage character character CO2 carbon steel, carbon steel, carbon steel e nang le k'hemik'hale ea mantlha | ||

| Mofuta oa ho fepa ka terata | Sututsa (hla-hla-la) /push-hu-la | |

| Phallo ea khase (L/min) | 15-20 | |

| Mokhoa oa ho pholisa | Phodiso ya metsi / Phodiso ya moya | |

| Sehlopha sa tšireletso ea likhetla | IP21S | |

| Boemo ba ho itšireletsa | H/B | |

MIG -M350/500/630

Mochini oa tjheseletsa o sirelelitsoeng ka khase oa CO2

MIG/MAG

Kamehla

Palo ea li-volts

Mesebetsi:

Mochini oa welding oa MIG/MAG o sirelelitsoeng ka khase, oa ho tjheseletsa oa tšepe-arc ka letsoho.

Indasteri ea likopo:

Kaho ea likepe, setshelo, mechini ea boenjiniere, indasteri ea petrochemical le sebopeho sa tšepe.

Likaroloana:

◆ E na le arc e tsitsitseng ea welding, spatter e ka tlaase, ponahalo e ntle ea weld le boleng bo phahameng ba welding;E na le litekanyo tse nepahetseng tsa taolo ea li-welding waveform, li-parameter tsa ts'ebetso ea welding le li-parameter tse khahlang le tsa khatello.Ho bonolo ho fetola liparamente le ho ipapisa le liparamente tse nepahetseng;

◆Basebelisi ba ka ipolokela.lintlha tse hlalositsoeng tsa ts'ebetso ea welding le ho laola ts'ebetso ea ho tjheseletsa le ho fana ka boiketlo bakeng sa ho tjheseletsa ho fapaneng ha seteishene se le seng ka ho tšoara ka hlooho le ho sebelisa mekhahlelo ea ts'ebetso ea welding;

Technical Parameters

| Mohlala | MIG- 350M | MIG- 500M | MIG-630M |

| Lebelo la motlakase / maqhubu a lekantsoeng | Tse tharo -phase380V (+/-) 10% 50Hz | ||

| Matla a kentsoeng a lekantsoeng (KVA) | 16.5 | 27.6 | 36 |

| Lintlha tse kentsoeng hajoale (A) | 25 | 42 | 54 |

| Reted output voltage (V) | 31.5 | 39 | 44 |

| E lekanyelitsoe ho tšoarella ha mojaro (%) | 100 | 100 | 60 |

| Voltage e se nang moroalo (V) | 68 | 68 | 86 |

| Sephetho sa hajoale (A) | 60-350 | 60-500 | 60-630 |

| Mofuta oa motlakase o tsoang (V) | 15-40 | 15-50 | 15-50 |

| Bophara ba terata e chesellang (mm) | 0.8, 1.0, 1.2 | 1.0, 1.2, 1.6 | 1.0, 1.2, 1.6 |

| Mofuta oa ho fepa ka terata | Sututsa | ||

| Mokhoa oa ho futhumatsa lithunya tsa welding | Phodiso ya metsi (he-tsi-tse) /air cooling | ||

| Sehlopha sa tšireletso ea likhetla | IP21S | ||

| Boemo ba ho itšireletsa | H/B | ||

ARC315/400/500/630/1000/1250/1500

DC arc welder e kentsoeng

MMA

Kelello ea matsoho

ho tjheseletsa arc

CAC-A

Gouging

Mesebetsi:

Sebetsa sa tšepe-arc ka letsoho.

Litšepe tse chesehang:

Tšepe ea carbon le tšepe e entsoeng ka tšepe.

Likaroloana:

◆ Phanele ea taolo e na le moralo o nepahetseng le ponts'o ea dijithale, le

welding current e ka fetoloa hantle;

◆ The arc striking current e ka fetoloa ka thoko, 'me e na le

ts'ebetso e ntle ea arc;

◆ The arc thrust current e ka fetoloa ka thoko;

◆ E na le mesebetsi ea ts'ireletso ea ts'ireletso joalo ka ts'ireletso ea mocheso,

tshireletso ya over-current and short-circuit protection.

Technical Parameter

| Mohlala | ARC-315 | ARC-400 | ARC-500 | ARC-630 | ARC-1000 | ARC-1500 |

| E lekantsoe matla a ho kenya / maqhubu | Mekhahlelo e meraro380V (+/-) 10% 50Hz | |||||

| E reitiloe matla a ho kenya (KVA) | 11.2 | 18.4 | 25 | 31.6 | 55 | 89 |

| Lintlha tse kentsoeng hajoale (A) | 17 | 28 | 38 | 52 | 83 | 140 |

| Reted output voltage (V) | 32.6 | 36 | 40 | 44 | 60 | 70 |

| E lekanyelitsoe ho tšoarella ha mojaro (%) | 60 | |||||

| Motlakase o sa keneng motlakase (V) | 70 | 70 | 81 | 86 | 86 | 86 |

| Sephetho sa hajoale (A) | 30~315 | 40-400 | 50 ~ 500 | 63-630 | 63-1000 | 63-1500 |

| Sehlopha sa tšireletso ea likhetla | IP21S | |||||

| Boemo ba ho itšireletsa | H/B | |||||

| mophodi wa ho phodisa | Pholiso ea moea | |||||

RETS'ELISITSOE

BINGOo tsoela pele ho etsa lipatlisiso le ho ntlafatsatheknoloji ea ho tjheseletsa e bohlalelumella lisebelisoa tse ngata tsa tjheseletsaea lefatše lohle

RETS'ELISITSOE

Joale e se e angoa ebile e ratoake linaha tse ngatanakong e tlang

RE TSOHLE

Re tla tsetela lisebelisoa tse ngata hor e tsoelang pele le d le tlhahisoeya pelele ka mohla u se ke ua emisa