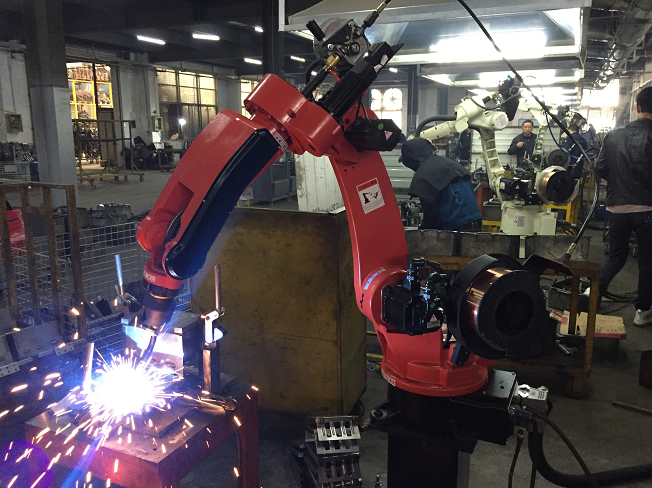

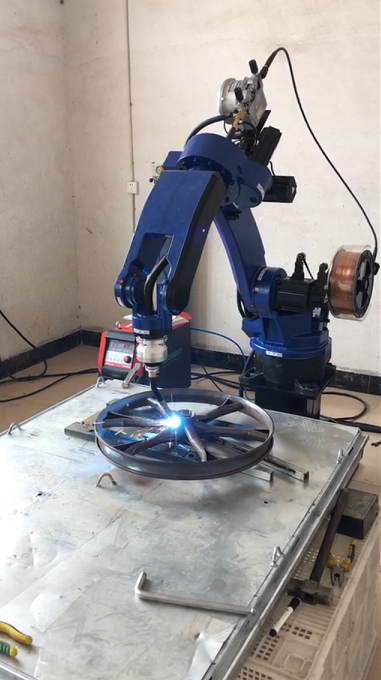

Mothating ona, liroboto tsa ho tjheseletsa li 'nile tsa sebelisoa haholo ho etsa likoloi, ho cheselletsa chassis ka motlakase, litšoantšo tsa skeleton tsa setulo, litšepe tsa li-slide, li-mufflers le li-converter tsa torque, joalo-joalo, haholo-holo tlhahiso le tlhahiso ea chassis ea ho cheselletsa le ho tjheseletsa.tshebediso.

Lik'hamphani tsa likoloi li nkile qeto ea ho hlomella li-welding joalo ka tloaelo, li sebelisa mofuta ona oa theknoloji ho ntlafatsa boleng ba tjheseletsa ea motlakase, esita le ho leka ho e sebelisa ho nka sebaka sa ts'ebetso ea li-arc.Nako e ka hare ho moeli o khutšoanyane le eona e fokotsehile haholo.Haufinyane tjena ho lokolotsoe roboto ea tjheseletsa e nang le karolo e tlase, e sebelisetsoang ho cheselletsa likarolo tse tlase tsa 'mele ka ho cheselletsa motlakase.Mofuta ona oa roboto e khuts'oane ea tjheseletsa e bohlale e ka bokelloa ka liroboto tse telele ho hlahisa le ho sebetsa pheletsong e kaholimo ea 'mele, ka hona ho fokotsa bolelele ba mohala o felletseng oa tlhahiso ea welding ea motlakase.

Boholo ba likarolo tsa chassis ea koloi tse kang li-axle tse ka morao, foreimi e nyenyane, letsoho la crank, tsamaiso ea ho emisa, mochine oa ho thothomela, joalo-joalo tse hlahisoang e lokela ho ba likarolo tsa ts'ireletso tse laoloang ke mokhoa oa MIG welding.E ka ba 1.5-4 mm.Senotlolo sa ho cheselletsa motlakase se laoloa ke li-lap joints le li-fillet joints.Boleng ba ho tjheseletsa motlakase le ho tjheseletsa bo phahame haholo, mme boleng ba yona bo kotsi ho ntlha ya polokeho ya koloi.Ka mor'a hore ho sebelisoe roboto ea ho cheselletsa, ponahalo le boleng ba bohlokoa ba ho cheseletsa li ntlafatsoa le ho feta, 'me ho tšepahala ha boleng ho tiisetsoa, katleho ea mosebetsi e fokotsehile,' me tikoloho ea basebetsi e ntlafatsoa.

Nako ea poso: Mar-21-2022