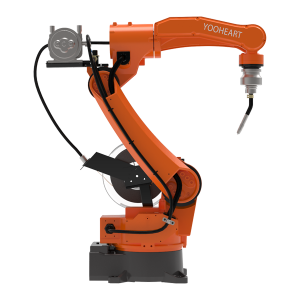

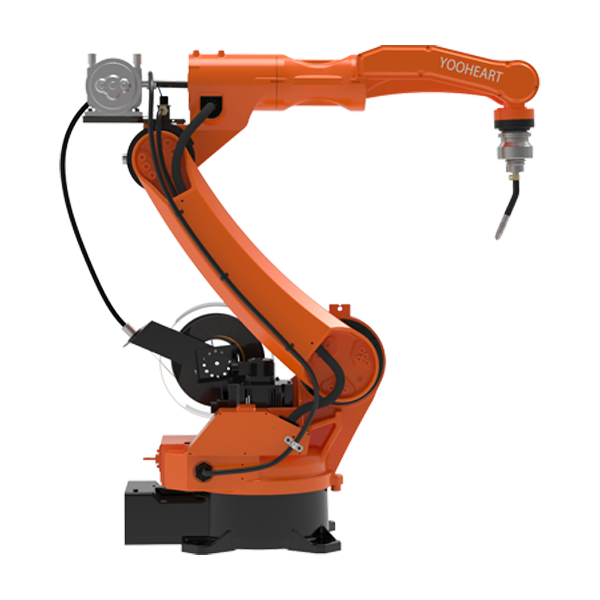

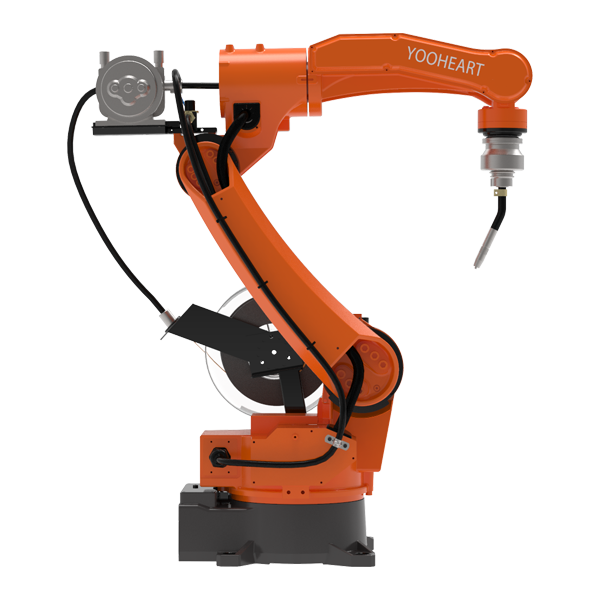

Liroboto tsa likoloi tsa arc welding

Kenyelletso ea Sehlahisoa

Lefatšeng la kajeno le susumetsoang ke thekenoloji, liroboto li bapala karolo e kholo tlhahisong ea hoo e ka bang halofo ea tse sebelisoang ho etsa litšepe. Tse ngata tsa tsonaliroboto tse cheselletsang li sebelisoa indastering ea likoloi. Lilemong tse 30 tse fetileng, liroboto tsa li-welding tsa likoloi li ntse li tšoarehile ho fetola indasteri. Ba entse hore likhoele tsa ho kopanya likoloi li potlake ha li ntse li bolokehile, li theko e tlaase, ebile li sebetsa hantle. Ana ke mabaka a ka sehloohong a entseng hore liroboto tsa likoloi li fetohe tsa bohlokoa ho fetoleng indasteri ea likoloi.

re rala tse ling tsa lisele tse sebetsang hantle le tse sebetsang hantle tsa liroboto tse fumanehang 'marakeng kajeno. Ka mekhoa ea rona ea li-welding tsa robotic, re fa baetsi ba likoloi tharollo e ka tšeptjoang e ka etsang likarolo tse likete tseo ba li hlokang ka lebelo le holimo, le tsitsitseng haholoanyane, ha ba ntse ba boloka tekanyo e phahameng ka ho fetisisa ea boleng ba sehlahisoa le ho tsitsisa.

Theknoloji Parameters

| Axis | Lekhetho | Pheta-pheta | Bokhoni | Tikoloho | Boima ba 'mele | Ho kenya |

| 6 | 6KG | ± 0.08mm | 3.7KVA | 0-45℃ 20-80%RH(Ha ho forsting) | 170KG | Phahamiso/ Ho phahamisetsa |

| Mofuta oa motsamao J1 | J2 | J3 | J4 | J5 | J6 | |

| ± 165º | '+80℃-150º | '+125º-75º | ± 170º | '+115º-140º | ± 220º | |

| Lebelo le phahameng J1 | J2 | J3 | J4 | J5 | J6 | |

| 145º/s | 133º/s | 145º/s | 217º/s | 172º/s | 500º/s |

Likarolo tsa mantlha

Lihlahisoa tsohle tsa boleng bo holimo

Sesebelisoa sa RV

1. Sebopeho sa motheo sa RV reducer haholo-holo se entsoe ka likarolo tsa phetisetso ea liboko, shaft, bearing, lebokose le lisebelisoa.

2. E ka aroloa likarolo tse tharo tsa motheo tsa sebopeho: 'mele oa lebokose, lisebelisoa tsa seboko, ho kopanya le shaft.

3. Phatlalatso ea RV e fokolang e tsitsitse, ho thothomela, tšusumetso le lerata le lenyenyane, sekhahla sa eona sa ho fokotsa se seholo,

Servo Motor

Ka litokelo tse fetang 100 tsa mantlha tse ikemetseng tsa thepa ea mahlale, Ruking e na le balekane ba fetang 100, marang-rang a eona a thekiso a koahelang libaka tse fetang 50 lefatšeng ka bophara. Sehlopha se amohela tsamaiso ea R&D ea maemo a lefats'e mme e na le sistimi ea boleng ea ISO9000 le ISO/TS16949.

Tsamaiso ea taolo

LNC ke lets'oao le holimo la 1 la sistimi ea taolo ho Aisa, 'me e na le mahlale a matle a taolo ea liroboto tsa gantry, SCARA, delta le tse 6 tse kopaneng ho fihlela litlhoko tsa mefuta eohle ho tsoa lits'ebetsong tse fapaneng tsa indasteri, joalo ka ho kopanya, tlhahlobo, sephutheloana, ho sebetsana le thepa. Re fana ka letoto le felletseng la lihlahisoa tse tloaelehileng le ts'ebeletso ea ho kopanya ho khotsofatsa litlhoko tsa ho itlhophisa.

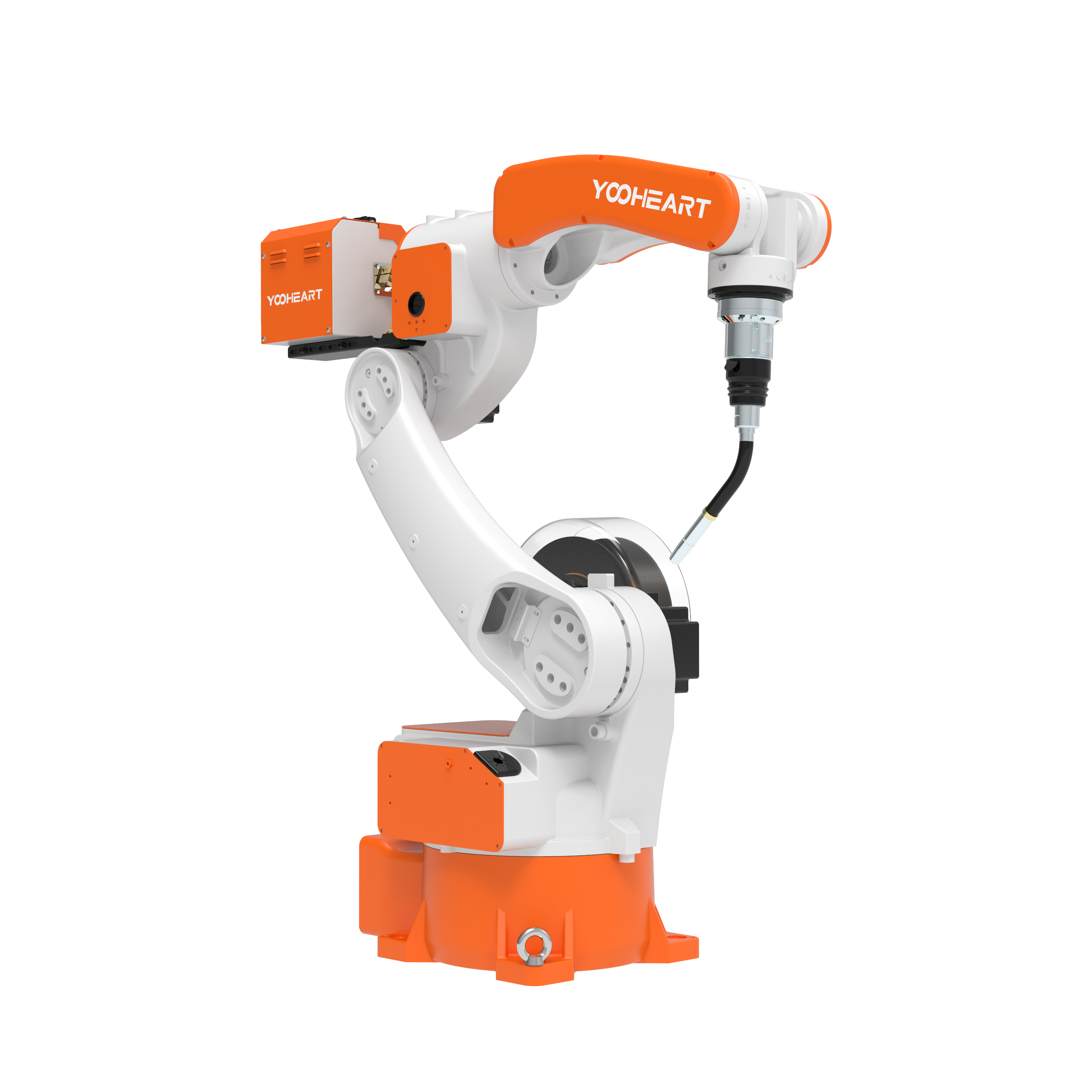

'Mele oa liroboto

Yooheart Robot e tla hlahloba lisebelisoa tsohle tse kenang, 'me tlhokahalo ea ho nepahala ke 0.01mm. Ke feela lisebelisoa tsa 'mele oa liroboto tse fihlelang litlhoko tse tla kena sehokelong se latelang bakeng sa ho kenya.

LETS'ELISO PONTS'O

Lihlahisoa tsohle tsa boleng bo holimo

PHAHAMENG E PHAHAMENG

Karabelo ea Khato e potlakileng

Mme boemo bo etella pele naheng

Boleng bo phahameng

Amohela Tlhophiso e Phahameng

Motsoako oa matla

Moralo o bobebe wa mmele

Compact

E bonolo ka sebopeho

Ho bonolo ho hlokomela

E boloka chelete e ngata

PHAHAMENG E PHAHAMENG

Lebelo le phahameng le botsitso litharollo tsa welding tse nepahetseng

KE HOBANE'NG LE RE KHETHA

tshebetso boleng ba tshebetso

TIISETSO

Tiisetso ea boleng e netefalitsoeng ka molao

FQA

P. Roboto ea Yooheart e ka eketsa li-axis tse kae?

A. Hajoale, roboto ea Yooheart e ka eketsa 3 axis ea kantle ho roboto e ka sebelisanang le roboto. Ka mantsoe a mang, re na le seteishene sa mosebetsi sa liroboto se tloaelehileng se nang le 7 axis, 8 axis le 9 axis.

P. Haeba re batla ho eketsa axis ho roboto, na ho na le khetho?

A. Na u tseba PLC? Haeba u tseba sena, roboto ea rona e ka buisana le PLC, ebe e fana ka matšoao ho PLC ho laola axis e ka ntle. Ka tsela ena, o ka eketsa li-axis tse 10 kapa ho feta. Khaello feela ea tsela ena ke hore axis e ka ntle e ke ke ea sebelisana le roboto.

P. PLC e buisana jwang le roboto?

A. Re na le boto ea i / O ka har'a khabinete ea taolo, ho na le 20 port port le 20input port, PLC e tla hokahanya boto ea I / O le ho amohela lipontšo ho tsoa ho roboto.

P. Na re ka eketsa boema-kepe bo bong ba I/o?

K. Bakeng sa ts'ebeliso ea weld feela, li-port tsena tsa I/O li lekane, haeba u hloka tse ling, re na le I/O e atolosang board. O ka eketsa tse ling tse 20 le tlhahiso.

Q. U sebelisa PLC ea mofuta ofe?

A. Hona joale re ka hokahanya Mitsubishi le Siemens hammoho le mefuta e meng.