Indasteri ea likoloi e tšoana le boqapi, e batlang ho nepahala ho sa feleng, lebelo le ts'epahalo ha ho etsoa likaroloana. Har'a likarolo tsa bohlokoa tsa likoloi, litsamaiso tsa mosi—haholo-holo lipeipi tsa ho ntša metsi—li phetha karolo ea bohlokoa tšebetsong ea koloi, taolong ea mesi le phokotso ea lerata. Ha bahlahisi ba ntse ba loanela ho fihlela litekanyetso tse thata tsa boleng le lipehelo tsa tlhahiso, liroboto tsa welding li hlahile e le lisebelisoa tsa bohlokoahali ha ho etsoa litsamaiso tsa mosi. Sengoliloeng sena se hlahloba hore na litsamaiso tsa welding tsa liroboto, tse kopantsoeng le lisebelisoa tse tsoetseng pele tsa maemo joalo karotary tilt positionerslelisebelisoa tse hlophisitsoeng, ba fetola tlhahiso ea liphaephe tsa mosi oa likoloi, ba phahamisa ts'ebetso, ho ts'oana le boleng ba sehlahisoa ho ea maemong ao ho neng ho sa lebelloa.

1. Ho rarahana ha Tlhahiso ea Pipe ea Exhaust

Liphaephe tsa ho ntša metsi li tlas'a maemo a feteletseng, ho akarelletsa le mocheso o phahameng, likhase tse senyang le ho thothomela ha mechine. Ho mamella liqholotso tsena, hangata li entsoe ka tšepe e sa hloekang kapa tšepe ea aluminized 'me li hloka litšepe tse se nang moroko, tse sa keneng moea ho pholletsa le lijeometri tse rarahaneng. Mekhoa ea khale ea ho cheseletsa ka letsoho hangata e thatafalloa ho boloka botsitso lits'ebetsong tse joalo, e lebisang ho bofokoli bo kang porosity, fusion e sa phethahalang, kapa ho sotha.

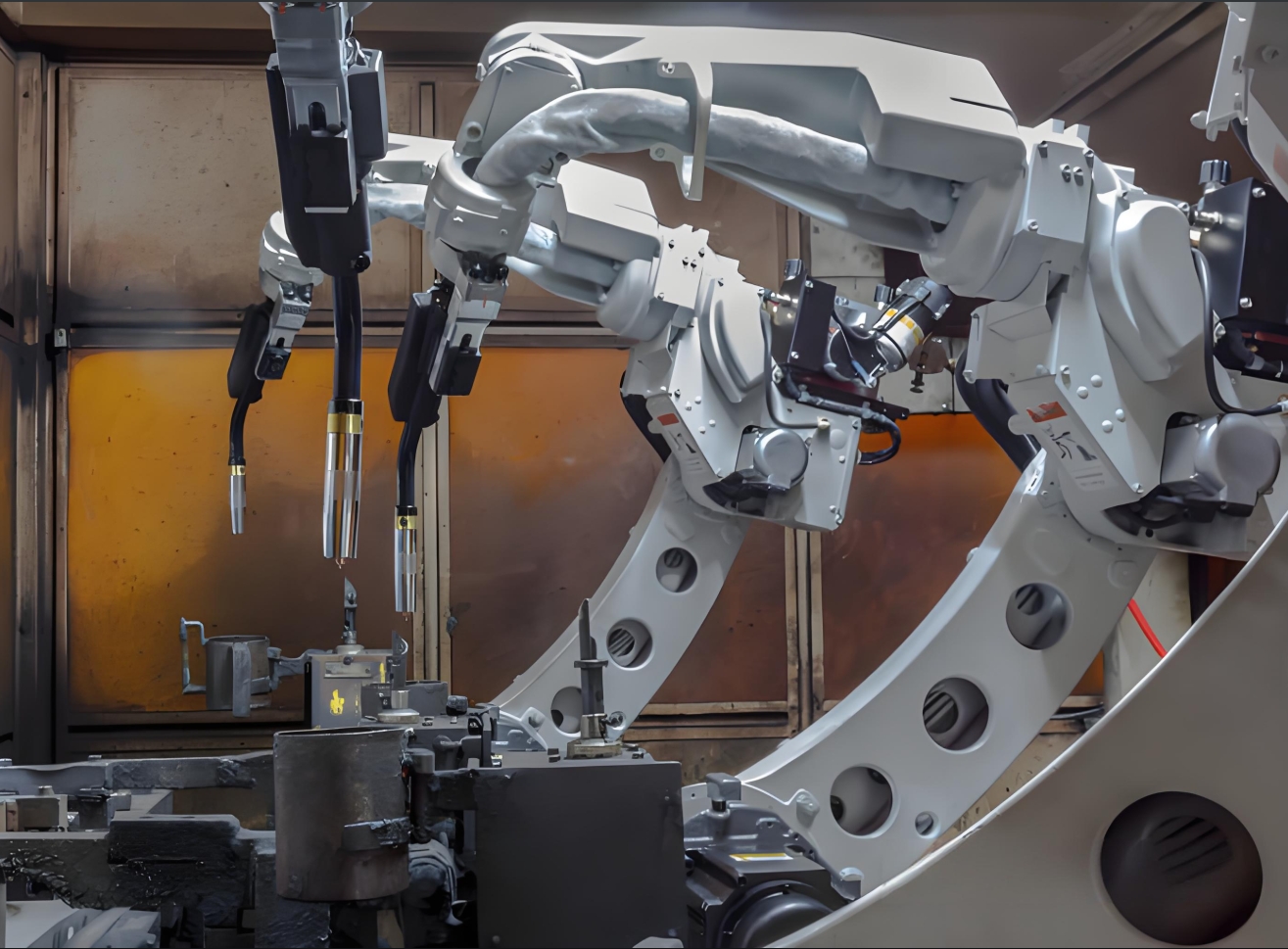

Leha ho le joalo, liroboto tse cheselletsang li sebetsa hantle ho sebetsana le mathata ana. E na le li-multi-axis axiculation le tse hokahaneng le litsamaiso tse nepahetseng tsa ho beha maemo, li fana ka li-welds tse se nang sekoli holim'a libaka tse kobehileng, li-flanges le manonyeletso - a bohlokoa bakeng sa ho netefatsa botšepehi ba tsamaiso ea ho tima.

2. Robotic Welding in Action: Likopo tsa Bohlokoa tsa Liphaephe tsa Exhaust

2.1 Tube-to-Flange le Tube-to-Muffler Welding

Sistimi ea ho felloa ke matla e na le likarolo tse ngata, ho kenyeletsoa liphaephe, li-converter tsa catalytic, li-resonator le li-mufflers. Sistimi ea ho cheselletsa liroboto e etsa hore ho hokahanngoa ha li-tubes ho li-flanges kapa matlong a li-muffler, ho netefatsa ho kenella ka mokhoa o ts'oanang le ho fokotsa libaka tse anngoeng ke mocheso (HAZ). Ka mohlala, a6-axis roboto e hlalositsoenge khona ho tsamaea ho potoloha selikalikoe sa phaephe, ho boloka li-angles tse nepahetseng tsa toche le lebelo la ho tsamaea esita le libakeng tse khoto.

2.2 Laser Welding for Thin-Walled Components

Hangata liphaephe tsa mehleng ea kajeno tsa ho ntša metsi li na le liqapi tse nang le marako a tšesaane ho fokotsa boima ba 'mele ha li ntse li boloka matla. Liroboto tsa li-welding tsa laser, tse nang le matla a phahameng a matla le li-weld seams tse tšesaane, li thibela ho loana le ho boloka thepa ea thepa. Sena se molemo ka ho khetheha bakeng sa lisebelisoa tsa tšepe tse sa hloekang, moo ho nepahetseng ho leng bohlokoa haholo.

2.3 Multi-Pas Welding bakeng sa Manonyeletso a Matenya

Bakeng sa litsamaiso tse boima tsa mosi ka har'a likoloi tsa khoebo, litsamaiso tsa robotic gas metal arc welding (GMAW) li sebelisa li-welds tse ngata ho theha manonyeletso a matla lipakeng tsa liphaephe tse nang le marako a teteaneng le mabakete. Adaptive welding algorithms e lokisa liparamente ka nako ea nnete ho amohela mefuta e fapaneng ea thepa.

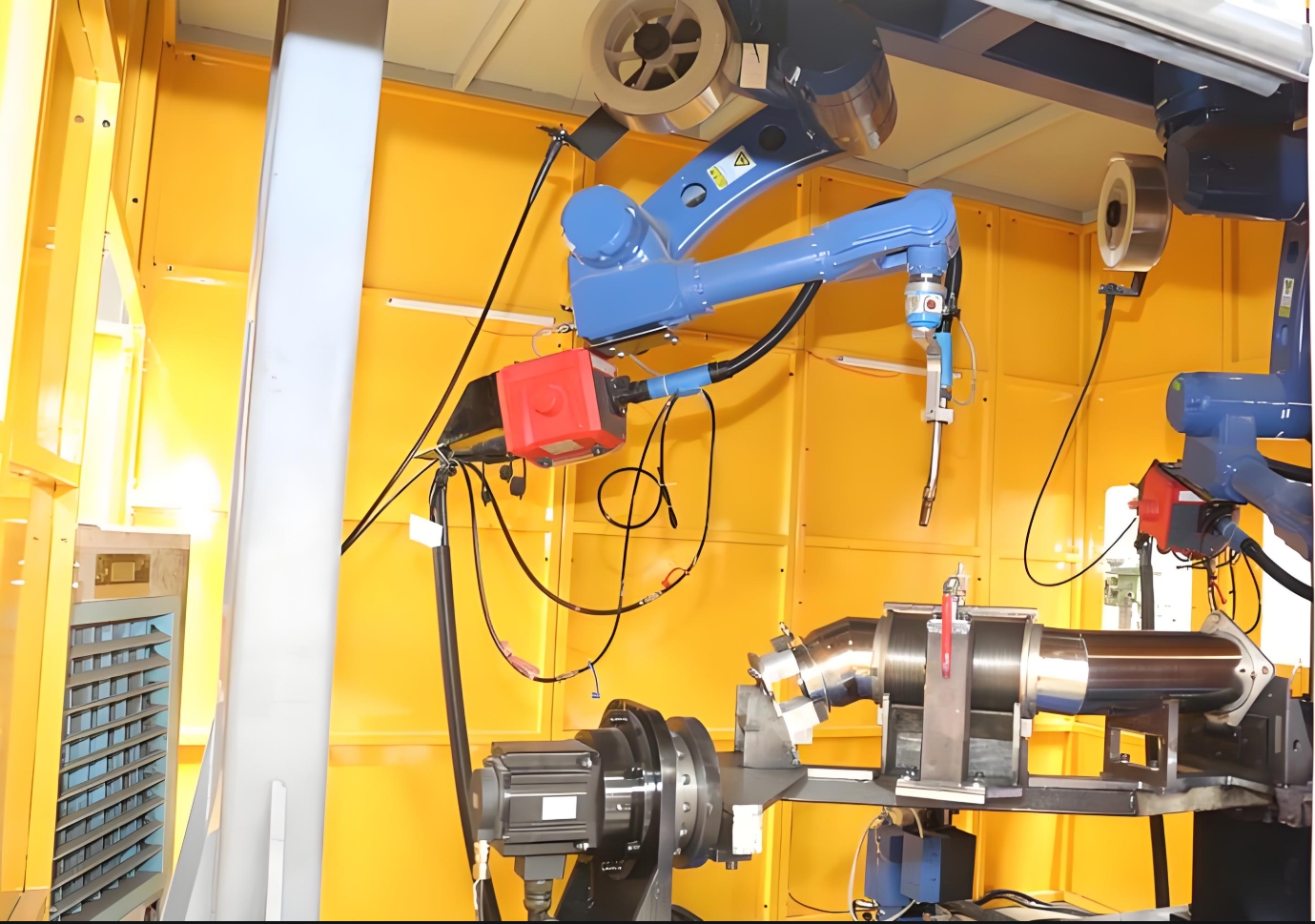

3. Ho Ntlafatsa ho Fetolana le Rotary Tilt Positioners

Ho sebetsa hantle ha sele ea liroboto ho ipapisitse le khokahano e se nang moeli lipakeng tsa roboto le mosebetsi.Li-positioners tsa rotaryke tsa bohlokoa ts'ebetsong ena, tse nolofalletsang ho potoloha le ho sekama ha lipeipi tsa mosi nakong ea ho cheselletsa. Melemo e kenyelletsa:

- Mokhoa o nepahetseng oa ho fihlella: Positioner e hlophisa phala bocha ho hlahisa seam ea weld sebakeng se bataletseng kapa se otlolohileng, se nolofatsa mananeo a liroboto le ho fokotsa linako tsa potoloho.

- Phokotso ea ho Beha maemo: Ka ho fetola sesebediswa sa mosebetsi ka matla, roboto e ka phethela li-welds tse ngata ka mokhoa o le mong, e fokotsa nako ea ho se sebetse.

- Ergonomics e ntlafalitsoeng: Basebelisi ba kenya / ba laolla likarolo ha roboto e ntse e tjheseletsa, e eketsa tlhahiso.

Mohlala, mochini o etsang liteishene tse peli o lumella phala e le 'ngoe hore e chesetsoe ha e 'ngoe e ntse e kentsoe, ho fihlela tlhahiso e tsoelang pele.

4. Precision Fixturing: The Backbone of Consistency

Customizedlisebelisoa tsa weldingLi bohlokoa bakeng sa ho tšoara likarolo tsa ho ntša metsi ka tatellano e nepahetseng nakong ea welding ea robotic. Lintlha tsa bohlokoa tsa moralo li kenyelletsa:

- Mekhoa ea ho Koetlisa: Li-clamp tsa moea kapa tsa haeteroliki li boloka liphaephe, li-flange le li-brackets ntle le ho senya bokaholimo.

- Modularity: Lisebelisoa tse fetohang ka potlako li amohela bophara bo fapaneng ba liphaephe kapa litlhophiso, tse loketseng tlhahiso ea mefuta e tsoakiloeng.

- Tsamaiso ea Mocheso: Lisebelisoa tse entsoeng ka thepa e thibelang mocheso li mamella ho pepeseha ha nako e telele ho li-welding arcs.

Lisebelisoa tse tsoetseng pele li kopanya li-sensor ho netefatsa ho beoa ha likarolo pele li tjheseletsa, ho felisa mefokolo e sa tsamaisaneng hantle.

5. Ho lekanya Phaello ea Katleho

Kamohelo ea litsamaiso tsa ho cheselletsa liroboto ha ho etsoa liphaephe tsa mosi ho fana ka lintlafatso tse ka lekanyetsoang:

- Pokotso ea Nako ea Potoloho: Sesepa sa robotic MIG se ka tlatsa weld e pota-potileng ka metsotsoana e 60, ha e bapisoa le metsotsoana e 180+ bakeng sa welding ka letsoho.

- Nako e Phahameng: Liroboto li sebetsa 24/7 ka nako e fokolang ea nako, li eketsa tlhahiso ea selemo ka 30-50%.

- Poloko ea Lintho: Taolo e nepahetseng ea parameter e fokotsa spatter le rework, e fokotsa litšenyehelo tse ka sebelisoang ka 15-20%.

Mohlala, morekisi oa likoloi oa Tier-1 o tlaleha aKeketseho ea 40% ea tlhahisoka mor'a ho kenya lisele tsa liroboto tse nang le li-positioner tse lumellanang bakeng sa kopano ea mokhathala.

6. Ho Phahamisa Boleng ho Maemo a Likoloi

Welding ea liroboto e netefatsa ho latela litekanyetso tsa boleng ba likoloi joalo ka IATF 16949:

- Pheta-pheta: Liroboto li pheta litsela tsa weld ka ho nepahala ha ± 0.1 mm, li felisa ho fetoha ha batho.

- Ho Fumana Sekoli: Litsamaiso tse kopaneng tsa pono kapa li-sensorer tsa ho shebella li-arc li lemoha ho se ts'oanehe lipakeng tsa ts'ebetso, e leng se bakang ho lokisoa hanghang.

- Litokomane: Sistimi ea othomathike e hlahisa lits'oants'o tse ts'oarehang tsa weld, tse bohlokoa bakeng sa tlhahlobo le ho hopola.

Litlhahlobo tsa morao-rao li senola hore litsamaiso tsa liroboto li fokotsa porosity le sekhahla sa crack ka 90% ha e bapisoa le mekhoa ea matsoho.

7. Moshoelella le Mekhoa ea Bokamoso

Baetsi ba likoloi ba ntse ba etelletsa pele ho tšoarella. Robotic welding e tšehetsa phetoho ena ka:

- Ho Fokotsa Tšebeliso ea Matla: Nako e sebetsang ea arc-on le litsela tse ntlafalitsoeng tsa ho sisinyeha li fokotsa tšebeliso ea matla.

- Ho Fokotsa Litšila: Litefiso tse phahameng tsa phallo ea pele li fokotsa sekhechana.

- Ho nolofaletsa Lightweighting: Precision welding e nolofalletsa tšebeliso ea lisebelisoa tse tsoetseng pele, tse tšesaane ntle le ho senya nako e telele.

Ke shebile pele,Liroboto tse chesehang tse tsamaisoang ke AIe tla eketsa ho ithuta ka mochini ho iketsetsa li-parameter bakeng sa lisebelisoa tse ncha, atheliroboto tse sebelisanang (cobots)e tla thusa basebetsi tlhahisong ea lihlopha tse nyane.

Qetello

Lefapheng la maemo a holimo la tlhahiso ea mosi oa likoloi, liroboto tse cheselletsang - tse matlafalitsoeng ke li-positioner tse bohlale le lisebelisoa - li emela sehlohlolong sa boenjineri bo nepahetseng. Ka ho iketsetsa mesebetsi e rarahaneng ea welding, litsamaiso tsena li matlafatsa bahlahisi ho fihlela linako tse potlakileng tsa potoloho, boleng bo botle le tlhahiso e mpe. Ha melaoana ea tlhahiso ea mosi e ntse e ntlafala le meralo ea likoloi e ntse e fetoha, theknoloji ea ho tjheseletsa liroboto e tla lula e le lejoe la motheo la mahlale a morao-rao, e lebisang indastering ea likoloi ho isa bokamosong bo botle le bo hloekileng.

Bakeng sa bahlahisi ba liroboto tsa indasteri, ho totobatsa bokhoni bona ts'ebetsong ea liphaephe tsa ho ntša metsi ha ho totobatse feela botsebi ba botekgeniki empa hape ho beha litharollo tsa bona e le balekane ba bohlokoa ho ntshetseng pele bokhabane ba tlhahiso ea likoloi.

Nako ea poso: Mar-21-2025