Selelekela

Lekala la tlhahiso ea likoloi le ntse le itšetleha haholo ka liroboto tsa indasteri ho fihlela ts'ebetso e nepahetseng, e sebetsang hantle le e tsitsitseng tlhahisong. Har'a lisebelisoa tsa bohlokoa ka ho fetisisa ke ho cheselletsa likarolo tsa koloi, haholo-hololi-axles(e tsejoang hape e leli-axle tsa koloikapali-axle tsa koloi), tse bohlokoa bakeng sa botsitso ba koloi, phetiso ea matla, le ho jara. Sengoliloeng sena se hlahloba hore na se tsoetse pele hakaelitsamaiso tsa ho tjheseletsa lirobotoba fetola tlhahiso ea li-axle le likarolo tse ling tsa likoloi, ha ba ntse ba totobatsa mantsoe a sehlooho ka bobelilikarolo tsa likoloileliroboto tsa ho cheselletsa.

Karolo ea 1: Likaroloana tsa Bohlokoa tsa Koloi ho Tsepamiso

Ho etsa likoloi ho kenyelletsa likopano tse rarahaneng, 'me likarolo tse latelang li le bohlokoa bakeng sa ts'ebetso ea likoloi. Mona ke tsenaholimo 5 likoloi motsoako mantsoe a sehloohoe amanang le puisano ena:

- Axle (Axle ea Koloi/Axle ea Koloi)

Li-axle li bohareng ba koloi ea koloi, mabili a hokahanyang le ho tšehetsa boima ba koloi. Precision welding e tiisa hore sebopeho se ts'epahala le ho tšoarella. - Sistimi ea ho emisoa

Likarolo tse kang matsoho a taolo le li-struts li hloka welding e matla ho mamella khatello ea 'mila. - Likarolo tsa Drivetrain

Likarolo tse kang matlo a fapaneng le li-transmission mounts li itšetlehile ka li-welds tse matla haholo. - Liforeimi tsa Chassis

Mokokotlo oa koloi, liforeimi tsa chassis li hloka boleng bo tsitsitseng ba weld bakeng sa polokeho. - Sistimi ea Exhaust

Litšepe tse rarahaneng tse holim'a mefuta e mengata le liphaephe li tlameha ho hanela mocheso le kutu.

Ho tsena,ho tjheseletsa ka axlee hlahella ka lebaka la ho rarahana ha eona le phello ea ts'ebetso ea koloi.

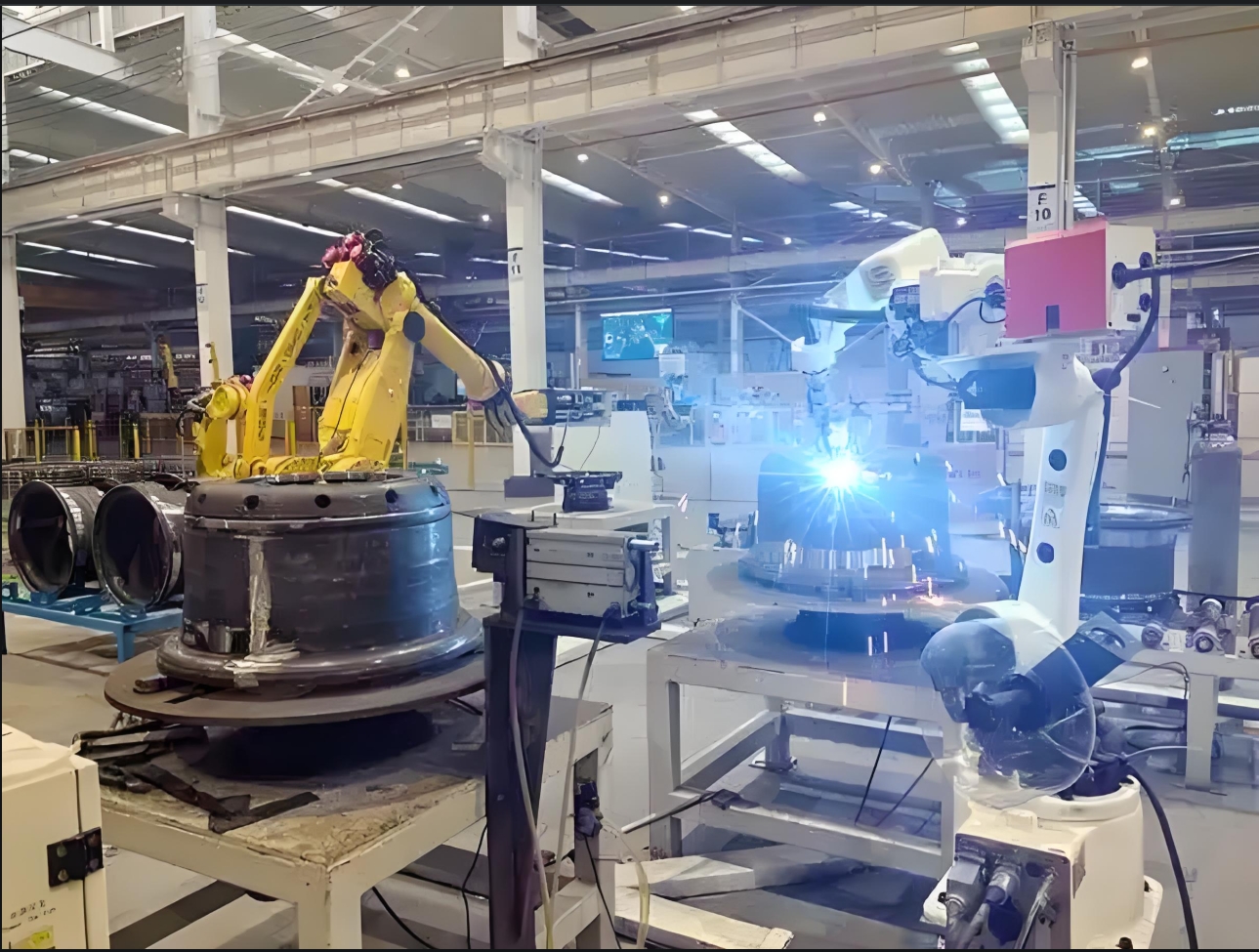

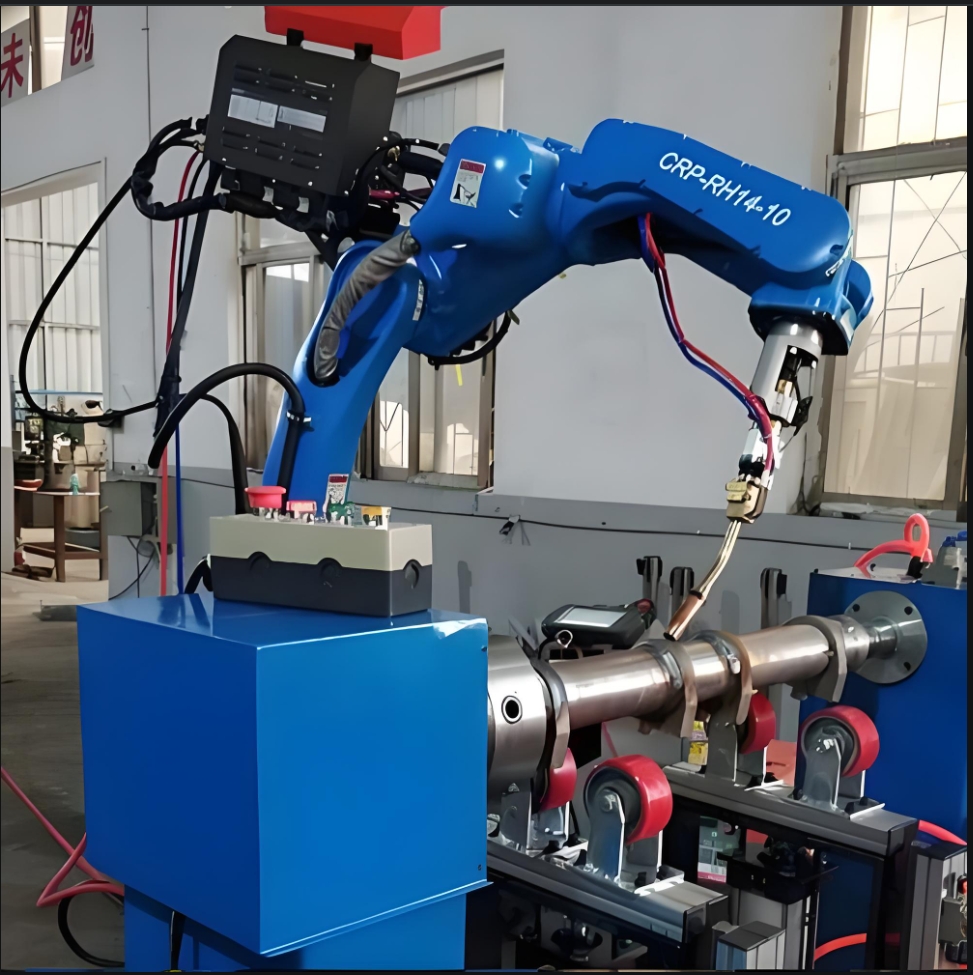

Karolo ea 2: Liroboto tsa Welding tsa Indasteri: Theknoloji le Bokhoni

Ea kajenolitsamaiso tsa ho tjheseletsa lirobotokopanya mahlale a tsoetseng pele ho fihlela maemo a likoloi. Ka tlase ke tsetop 5 tjheseletsa roboto mantsoe a bohlokoa:

- Automated Welding

Automation e etsa bonnete ba ho pheta-pheta le ho fokotsa liphoso tsa batho tlhahisong e phahameng ea molumo. - Arc Welding (MIG/TIG)

E ratoa bakeng sa ho etsoa ha li-axle ka lebaka la ho kenella ho tebileng le ho thehoa ha manonyeletso a matla. - Laser Welding

E sebelisoa bakeng sa mesebetsi e nepahetseng haholo, joalo ka ho cheselletsa li-axle shafts tse nang le ho khopama ho fokolang. - Spot Welding

E nepahetse bakeng sa ho kopanya lishiti tsa tšepe tse fetang ka har'a likarolo tse emisitsoeng kapa tsa chassis. - Liroboto tse Tšebelisano (Cobots)

Ntlafatsa ho feto-fetoha ha maemo libakeng tsa tlhahiso e tsoakaneng, ho sebetsa le litsebi tsa theknoloji.

Theknoloji ena e nolofalletsa baetsi ho finyellaho tjheseletsa lefelaka likarolo tsa bohlokoa joalo ka li-axles.

Karolo ea 3: Li-axle tsa Welding tse nang le Liroboto tsa Indasteri: Ts'ebetso le Melemo

Mohato oa 1: Moralo le Lenaneo

Axle welding e qala ka lipapiso tsa CAD/CAM ho ntlafatsa litsela tsa weld. Liroboto li etselitsoe metsamao ea li-axis tse ngata, ho netefatsa phihlello ea lijeometri tse rarahaneng.

Mohato oa 2: Tokisetso ea Lintho

Li-axles hangata li entsoe ka tšepe e matla haholo kapa li-alloys tsa aluminium. Lisebelisoa tsa liroboto li hloekile esale pele le likarolo tsa clamp ho fokotsa ho se lumellane.

Mohato oa 3: Ts'ebetso ea Welding

- Arc Welding: E sebelisoa bakeng sa matlo a maholo a li-axle, ho netefatsa hore ho na le seams se tebileng, se tšoanang.

- Laser Welding: E sebelisoa ho manonyeletso a nepahetseng ka meralo e bobebe ea li-axle.

- Seam Tracking Sensors: Ho lefella ho se lumellane ha lintho ka nako ea sebele.

Melemo ea ho Welding ea Robotic Axle:

- Matla a Matlafalitsoeng: Li-welds tse tsitsitseng li fokotsa lintlha tse fokolang.

- Nako ea Potlako ea Potoloho: Liroboto li sebetsa 24/7, li eketsa tlhahiso.

- Ho Boloka Litšenyehelo: Litefiso tse tlase tsa lits'enyehelo le litšenyehelo tse fokotsehileng tsa basebetsi.

- Polokeho: E felisa ho pepesehela litlhase le mosi bakeng sa basebetsi.

Karolo ea 4: Mekhoa ea Indasteri e Shaping Robotic Welding

- Taolo ea Boleng ba Matla a AI

Li-algorithms tsa ho ithuta ka mochini li sekaseka botšepehi ba weld, ho tšoaea liphoso ka nako ea nnete. - Litlhoko tse bobebe

Liroboto li ikamahanya le lisebelisoa tse tsoetseng pele tse kang aluminium-carbon composite bakeng sa li-axle tsa koloi ea motlakase (EV). - IoT Integration

Liroboto tse bohlale li fetisetsa data ea ts'ebetso ho litsamaiso tse bohareng bakeng sa tokiso e boletsoeng esale pele. - Moshoelella

Mekhoa ea ho cheseletsa e sebetsang hantle ka matla e fokotsa likhase tsa khabone.

Mekhoa ena boemolitsamaiso tsa ho tjheseletsa lirobotoe le ea bohlokoa lifemeng tsa sejoale-joale tsa likoloi.

Karolo ea 5: Mathata le Litharollo

Le ha ho tjheseletsa ha roboto ho fana ka melemo e meholo, mathata a ntse a tsoela pele:

- Matsete a Pele a Phahameng: E fokotsoe ke ROI ea nako e telele ho tloha tlhahiso e eketsehileng.

- Complex Programming: E nolofalitsoe ka li-interfaces tse bonolo tsa basebelisi le lisebelisoa tsa papiso tse kantle ho marang-rang.

- Phapang ea Lintho: E eketsoa ka li-sensor tse feto-fetohang le liphetoho tse tsamaisoang ke AI.

Bakeng sa welding ea axle, sebelisana le ba nang le boiphihlelobaetsi ba liroboto tsa indasterie netefatsa litharollo tse lokiselitsoeng.

Qetello

Ho chesetsoa ha likarolo tsa likoloi joalo ka li-axle ho fana ka mohlala oa matla a ho fetola aliroboto tsa indasteri. Ka ho sebelisa cheleteho tjheseletsa ka boiketsetso,ho cheseletsa arc, lelaser tjheseletsathekenoloji, bahlahisi ba finyella ho nepahala le ho sebetsa ka mokhoa o ke keng oa lekanngoa. Ha indasteri ea likoloi e ntse e tsoela pele-haholo-holo ka ho phahama ha li-EVs-litsamaiso tsa ho tjheseletsa lirobotoe tla lula e le bohareng ba ho hlahisa likarolo tse tšoarellang, tse sebetsang hantle haholo. Bakeng sa likhoebo tse batlang ho ntlafatsa mekhoa ea tsona ea tlhahiso, ho tsetela ho liroboto tse tsoetseng pele tsa welding ha se khetho feela empa ke tlhokahalo.

Mantsoe a sehlooho: Axle, Vehicle Axle, Suspension Systems, Drivetrain Components, Chassis Frames; Ho tjheseletsa ka Othomathike, Litsamaiso tsa ho Welding tsa Robotic, Arc Welding, Laser Welding, Spot Welding.

Nako ea poso: Apr-02-2025