Selelekela

Indasteri ea likoloi esale e le pula-maliboho ea ho sebelisa mahlale a morao-rao ho ntlafatsa ts'ebetso, ho nepahala le ho hlaka. Har'a likarolo tsa eona tsa bohlokoa ka ho fetisisa ke foreimi ea koloi-mokokotlo oa mohaho o tiisang tšireletseho, nako e telele le ts'ebetso. Ha litlhoko tsa thepa e bobebe, ho itloaetsa, le tlhahiso e potlakileng e ntse e eketseha, bahlahisi ba ntse ba fetohela ho liroboto tsa indasteri ho fetola maqheka a foreimi. Sengoliloeng sena se hlahloba kamoo liroboto li fetolang tlhahiso ea liforeimi tsa likoloi, ho tloha ts'ebetsong ea thepa ho ea ho li-welding le taolo ea boleng, ha li ntse li sebetsana le mathata le mekhoa ea nako e tlang lefapheng lena le matla.

Karolo ea 1: Karolo ea Bohlokoa ea Liforeimi tsa Likoloi ho Moralo oa Likoloi

Liforeimi tsa likoloi, tseo hangata li bitsoang chassis, li sebetsa e le motheo oa litsamaiso tsohle tsa likoloi. Ba tlameha ho mamella khatello e matla ea maikutlo, ba monye tšusumetso ea ho thulana, le ho tšehetsa boima ba koloi le bapalami ba eona. Liforeimi tsa sejoale-joale li entsoe ka lisebelisoa tse tsoetseng pele joalo ka tšepe e matla haholo, li-alloys tsa aluminium, esita le metsoako ea carbon fiber ho leka-lekanya matla le phokotso ea boima ba 'mele.

Leha ho le joalo, ho etsa libopeho tsena tse rarahaneng ho hloka ho nepahala ho feteletseng. Esita le ho kheloha ho fokolang ha ho tsamaisana le welding kapa ho kopanya likarolo ho ka senya polokeho le ts'ebetso. Mekhoa ea khale ea matsoho e thatafalloa ho fihlela mamello e thata e batloang ke litekanyetso tsa kajeno tsa likoloi, e leng se etsang hore ho be le tlhoko e matla ea ho iketsetsa lintho.

Karolo ea 2: Liroboto tsa Liindasteri ho Tlhahiso ea Frame: Lisebelisoa tsa Bohlokoa

2.1 Ts'ebetso ea Lintho le Tokiso ea Karolo

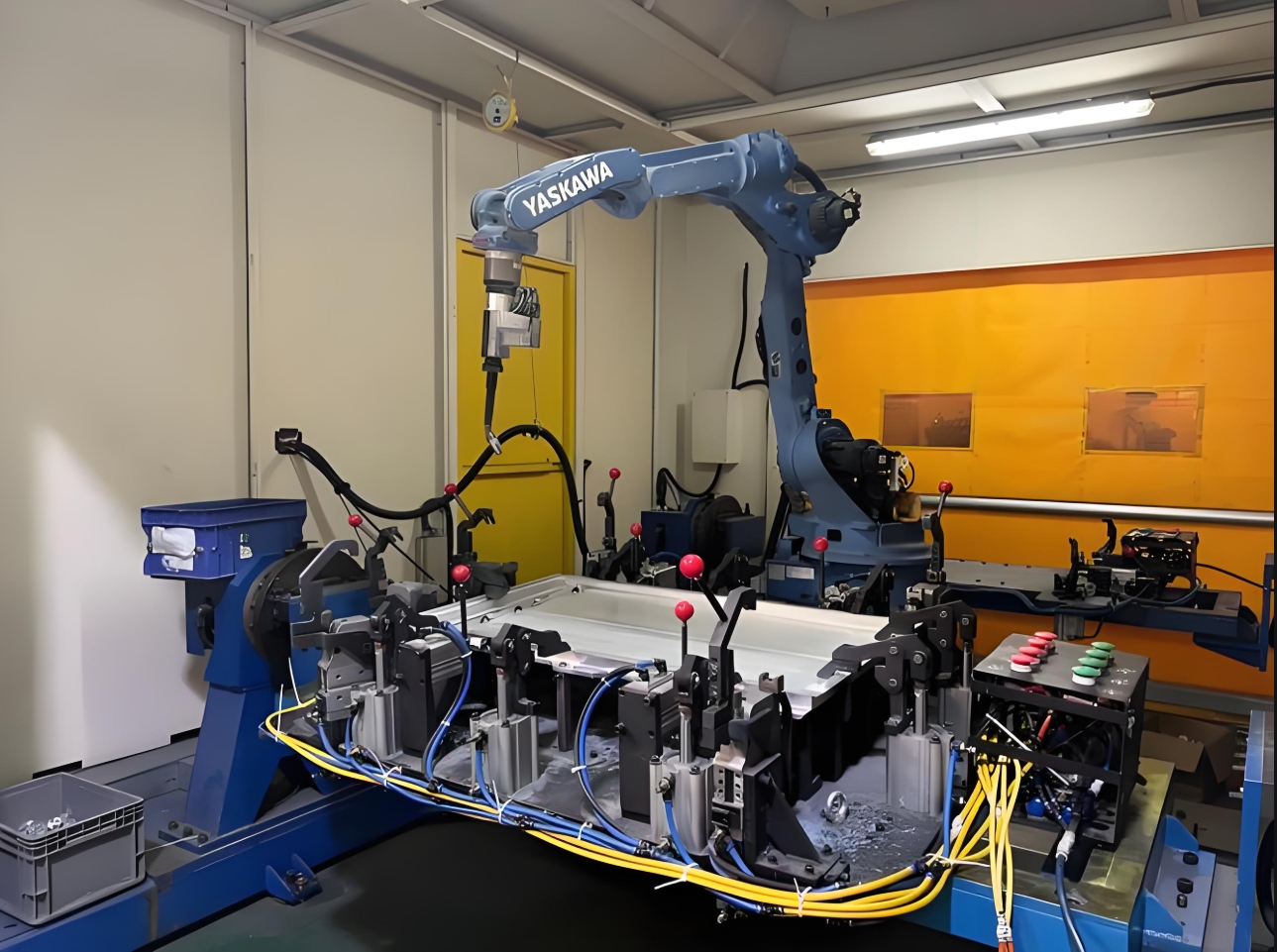

Tlhahiso ea liforeimi tsa likoloi e qala ka ts'ebetso ea thepa e tala. Liroboto tsa indasteri tse nang le li-grippers tse tsoetseng pele le litsamaiso tsa pono li sebetsa hantle ho sebetsana le lishiti tse ngata tsa tšepe, li-tubes le likarolo tse seng li entsoe. Ka mohlala:

- Ho qhekella ka tšepe: Liroboto tse sehiloeng pele le ho etsa litšepe kapa maqephe a aluminium hore e be liporo tsa foreimi, li-crossmembers, le masakaneng a nang le limilimithara tse nepahetseng.

- Ho sebetsana le thepa e kopantsoeng: Liroboto tse sebelisanang (li-cobots) li laola ka mokhoa o sireletsehileng lisebelisoa tse bobebe empa tse senyehang joalo ka carbon fiber, ho fokotsa litšila le liphoso tsa batho.

2.2 Theknoloji ea ho cheselletsa le ho kopanya

Welding e ntse e le mohato o matla ka ho fetisisa oa liroboto tlhahisong ea liforeimi. Sistimi ea sejoale-joale ea liroboto e fana ka botsitso bo ke keng ba lekanngoa ho pholletsa le lintlha tse likete tsa weld:

- Resistance spot welding: Liroboto tse nang le li-axis tse ngata li etsa welding ea lebelo le holimo holim'a liforeimi tsa tšepe, ho netefatsa matla a kopaneng a tšoanang.

- Ho chesoa ka laser: Liroboto tse nepahetseng tse nang le lihlooho tsa laser li theha maqhama a se nang moeli bakeng sa liforeimi tsa aluminium, ho fokotsa ho sotheha ha mocheso.

- Tšebeliso ea sekhomaretsi: Liroboto li sebelisa likhomaretsi ka mekhoa e rarahaneng ho kopanya liforeimi tse kopaneng tsa tšepe, e leng mokhoa oo ho leng thata ho o etsa ka letsoho.

Mohlala: Moetsi oa likoloi oa Europe ea etelletseng pele o fokotsitse bofokoli ba welding ka 72% ka mor'a ho sebelisa sehlopha sa liroboto tse 6-axis tse nang le tokiso ea tsela e feto-fetohang, tse khonang ho lokisa liparamente tsa weld ka nako ea nnete ho latela maikutlo a sensor.

2.3 Kopano le Kopanyo

Kopano ea foreimi e kenyelletsa ho kopanya lithapo tse emisitsoeng, masakaneng a enjine le likarolo tsa polokeho. Liroboto tse nang le matsoho a mabeli li etsisa boqhetseke ba motho ho tiisa liboutu, ho kenya lihlahla, le ho hokahanya li-subassemblies. Litsamaiso tse tataisoang ke pono li netefatsa hore likarolo li behiloe ka har'a mamello ea ± 0.1 mm, ea bohlokoa bakeng sa ho boloka tumellano ea drivetrain.

2.4 Tiisetso ea Boleng le Metrology

Tlhahlobo ea kamora tlhahiso e bohlokoa bakeng sa ho latela melao ea polokeho. Sistimi ea liroboto joale e sebetsa:

- 3D laser scanning: Liroboto li etsa 'mapa oa li-geometri tsa foreimi eohle ho bona ho fosahala kapa ho fosahala.

- Tlhahlobo ea Ultrasonic: Li-probes tse ikemetseng li hlahloba botšepehi ba weld ntle le ho senya bokaholimo.

- Ho lemoha sekoli se tsamaisoang ke AI: Li-algorithms tsa ho ithuta ka mochini li sekaseka phepelo ea kh'amera ho tseba li-micro-cracks kapa ho se lumellane ha li-coating.

Karolo ea 3: Melemo ea Robotic Automation ho Tlhahiso ea Frame

3.1 Ho nepahala le ho Pheta-pheta

Liroboto tsa indasteri li felisa ho fetoha ha batho. Sele e le 'ngoe ea liroboto e ka boloka ho pheta-pheta ha 0.02 mm ho pholletsa le 24/7 ea potoloho ea tlhahiso, ho netefatsa hore foreimi e' ngoe le e 'ngoe e kopana le litlhaloso tse hlakileng tsa moralo.

3.2 Ntlafatso ea Tšireletseho ea Basebetsi

Ka ho iketsetsa mesebetsi e kotsi joalo ka welding kapa ho phahamisa boima, bahlahisi ba tlalehile phokotso ea 60% ea likotsi tsa mosebetsing tse amanang le ho etsa foreimi.

3.3 Tšebeliso e Ntle ea Litšenyehelo

Le ha matsete a pele a le bohlokoa, liroboto li fokotsa litšenyehelo tsa nako e telele ka:

- 30–50% linako tsa potoloho e potlakileng

- 20% litšila tse tlase tsa thepa

- Phokotso ea 40% ea litšenyehelo tsa rework

3.4 Scalability le Fetobello

Lisele tsa liroboto tsa modular li lumella bahlahisi hore ba potlakele ho lokisa mela ea tlhahiso bakeng sa meralo e mecha ea foreimi. Mohlala, liforeimi tsa koloi ea motlakase (EV) tse nang le li-betri li ka kopanngoa le lits'ebetso tse teng ka nako e fokolang.

Karolo ea 4: Ho Hlōla Mathata ho Tlhahiso ea Frame ea Liroboto

4.1 Mathata a Tšebelisano le Lintho

Ho fetohela ho liforeimi tse nang le lisebelisoa tse ngata (mohlala, tse nyalisitsoeng tsa tšepe-aluminium) li hloka hore liroboto li sebetse ka mekhoa e sa tšoaneng ea ho kopanya. Litharollo li kenyelletsa:

- Lihlooho tsa li-welding tsa Hybrid tse kopanyang mahlale a arc le laser

- Magnetic grippers bakeng sa ho sebetsana le litšepe tse se nang ferrous

4.2 Mathata a Lenaneo

Software ea offline roboto programming (OLP) joale e lumella lienjiniere ho etsisa le ho ntlafatsa phallo ea mosebetsi oa liroboto ka dijithale, ho fokotsa nako ea ho laela ka 80%.

4.3 Likotsi tsa Cybersecurity

Ha tlhahiso ea foreimi e ntse e hokahane le ho feta ka Industrial IoT, bahlahisi ba tlameha ho kenya tšebetsong liprothokholo tsa puisano tse patiloeng le liapdeite tsa kamehla tsa firmware ho sireletsa marang-rang a liroboto.

Karolo ea 5: Bokamoso ba Tlhahiso ea Frame ea Robotic

5.1 AI-Driven Driven Adaptive Manufacturing

Liroboto tsa moloko o latelang li tla sebelisa bohlale ba maiketsetso ho:

- Lisebelisoa tsa ho ikemela tse ipapisitseng le botenya ba thepa

- Ho bolela esale pele le ho lefella ho roala ha lisebelisoa

- Ntlafatsa tšebeliso ea matla nakong ea tlhokeho e phahameng

5.2 Tšebelisano ea Batho le Liroboto

Li-cobots tse nang le manonyeletso a lekanyelitsoeng ka matla li tla sebetsa hammoho le litsebi bakeng sa liphetoho tsa ho qetela tsa foreimi, ho kopanya ho etsa liqeto tsa batho le ho nepahala ha robotiki.

5.3 Tlhahiso ea Moshoelella

Sistimi ea liroboto e tla bapala karolo ea bohlokoa ho fihlelleng tlhahiso e chitja:

- Ho qhaqholla ha liforeimi tsa ho qetela tsa bophelo bakeng sa ho sebelisoa hape

- Precision material deposition ho fokotsa ts'ebeliso ea thepa e tala

Qetello

Ho kopanngoa ha liroboto tsa indasteri tlhahisong ea foreimi ea likoloi ho emela ho fetang feela tsoelo-pele ea thekenoloji-e bontša phetoho ea bohlokoa tseleng eo likoloi li qapiloeng le ho hahoa ka eona. Ka ho fana ka ho nepahala ho ke keng ha bapisoa, ho sebetsa hantle le ho ikamahanya le maemo, litsamaiso tsa liroboto li matlafatsa bahlahisi ho fihlela litlhoko tse tsoelang pele tsa likoloi tse sireletsehileng, tse bobebe le tse tšoarellang. Ha AI, li-sensor tse tsoetseng pele, le mahlale a matala a ntse a tsoela pele ho hola, tšebelisano lipakeng tsa liroboto le boenjiniere ba likoloi ntle le pelaelo e tla lebisa indasteri ho maemo a neng a e-so ka a bonoa a boqapi.

Bakeng sa lik'hamphani tse sebetsanang le liroboto tsa indasteri, phetoho ena e fana ka menyetla e mengata ea ho sebelisana le baetsi ba likoloi ho hlakisa bokamoso ba motsamao - foreimi e le 'ngoe e entsoeng hantle ka nako.

Palo ea Mantsoe: 1,480

Melao ea Bohlokoa: Liroboto tsa foreimi ea likoloi, li-welding system tsa liroboto, AI tlhahisong, liroboto tse sebelisanang, tlhahiso e tsitsitseng

SEO likhothaletso: Kenyelletsa litlhaloso tsa meta tse lebisitseng "automotive frame automation" le "liroboto tsa indasteri bakeng sa chassis ea koloi." Sebelisa lihokelo tsa ka hare ho lithuto tsa liketsahalo tse amanang kapa maqephe a sehlahisoa.

Nako ea poso: Mar-26-2025