Ts'ebeliso ea liroboto tsa tjheseletsa e lokela ho laola ka tieo boleng ba ho lokisa likarolo le ho ntlafatsa ho nepahala ha kopano ea litšepe. Boleng ba bokaholimo, boholo ba groove le ho nepahala ha kopano ea likarolo li tla ama phello ea ho latela seam ea welding. Boleng ba ho lokisa likarolo le ho nepahala ha kopano ea weldment e ka ntlafatsoa ho tloha likarolong tse latelang.

(1) Kopanya mokhoa o khethehileng oa ho cheselletsa liroboto, 'me u etse melao e thata ea ts'ebetso mabapi le boholo ba likarolo, li-groove tsa weld, le litekanyo tsa kopano. Ka kakaretso, mamello ea likarolo le litekanyo tsa groove li laoloa ka hare ho ± 0.8mm, 'me phoso ea tekanyo ea kopano e laoloa ka hare ho ± 1.5mm. Monyetla oa mefokolo ea welding joalo ka li-pores le undercuts ho weld e ka fokotsoa haholo.

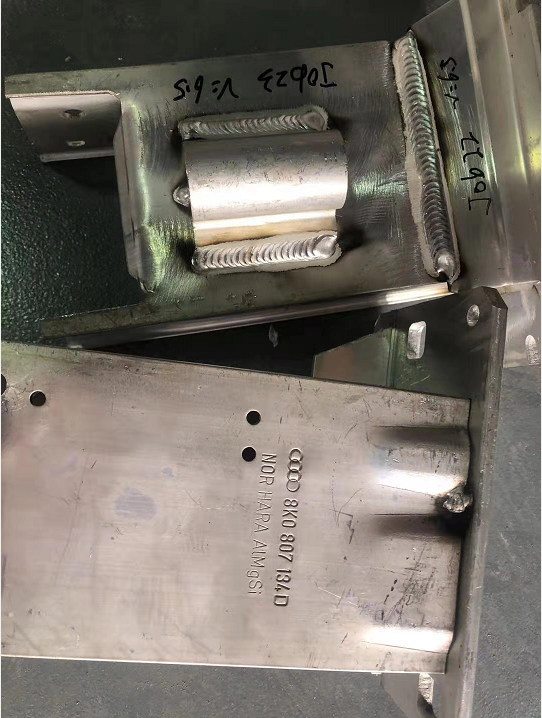

(2) Sebelisa lisebelisoa tsa kopano tse nepahetseng haholo ho ntlafatsa ho nepahala ha kopano ea li-welds.

(3) Li-welding seams li lokela ho hloekisoa, ntle le oli, mafome, li-welding slag, li-cutting slag, joalo-joalo, le li-primers tse rekisoang li lumelloa. Ho seng joalo, e tla ama lebelo la katleho ea ho khantša arc. Welding ea tack e fetoloa ho tloha ho li-electrode welding ho ea ho welding e sirelelitsoeng ka khase. Ka nako e ts'oanang, likarolo tsa tjheseletsa tsa letheba li belisoa ho qoba li-crusts tse setseng tsa slag kapa li-pores ka lebaka la ho tjheseletsa, e le ho qoba ho se tsitse ha arc esita le spatter.

Nako ea poso: Sep-11-2021